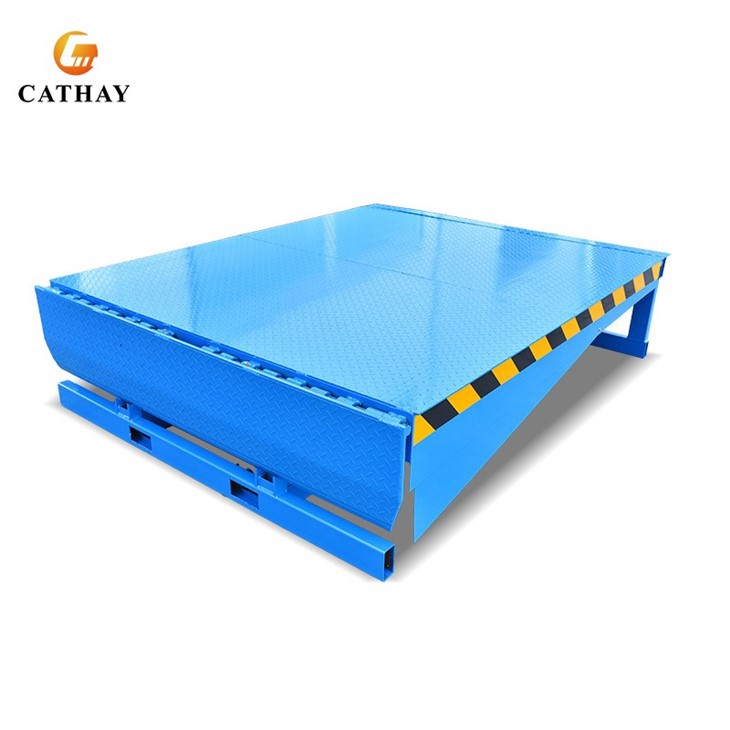

Shandong Cathay Machinery Co., Ltd. is one of the most experienced manufacturers and suppliers of hydraulic disassembly dock bridge platform in China. We warmly welcome you to buy discount hydraulic disassembly dock bridge platform for sale here from our factory. Quality products and reasonable price are available.

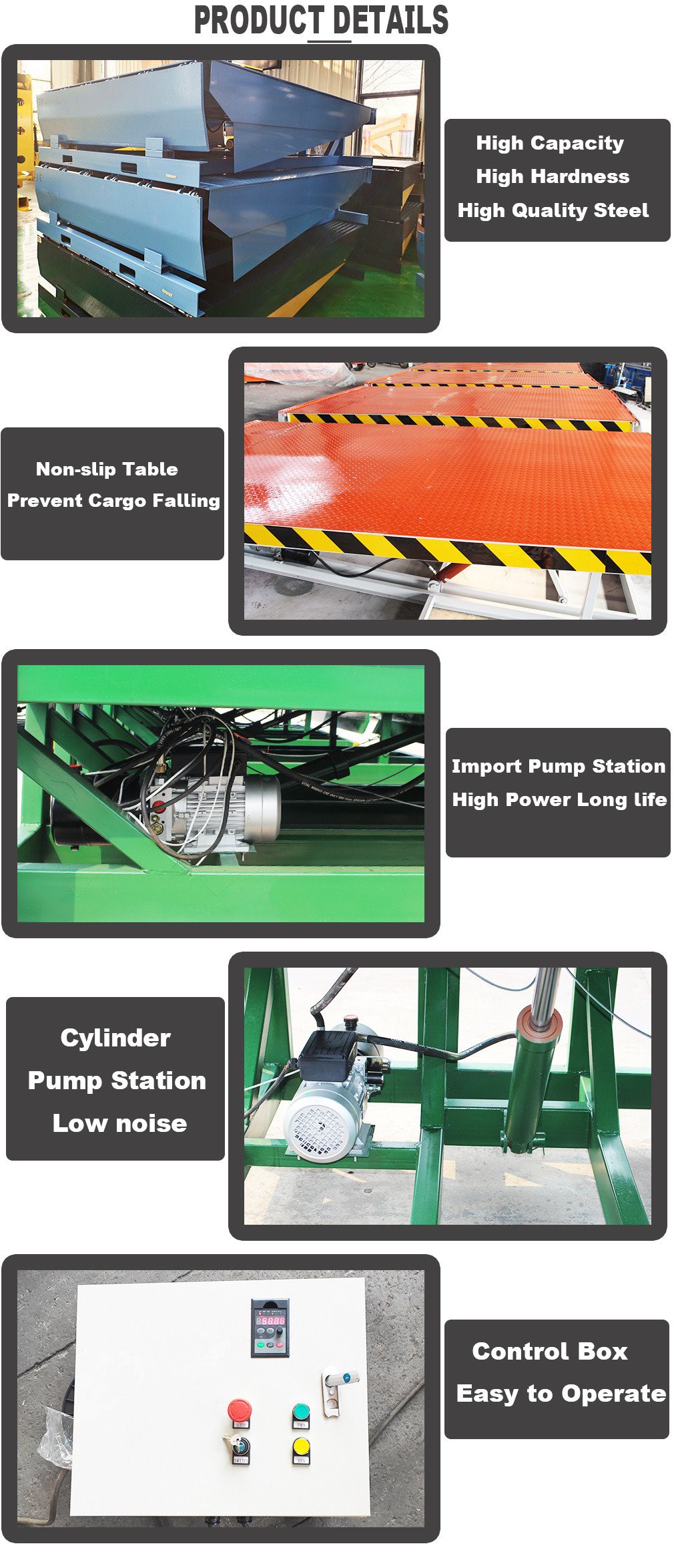

The CATHAYLIFT hydraulic dock bridge platform is equipped with adjustable safety pillars. During maintenance, the adjustment plates are reinforced through support columns to ensure stable operation. Arc-shaped anti-collision rubber blocks are set at the four corners, and the deep-buried bolt installation technology is adopted to prevent the protruding parts from scraping. The buffer structure effectively absorbs the collision impact. The overall design enhances safety protection and is suitable for ship maintenance scenarios, taking into account both equipment durability and operational reliability

|

Model No. |

CDR-6 |

CDR-8 |

CDR-10 |

CDR-12 |

|

|

Load Capacity (t) |

6 |

8 |

10 |

12 |

|

|

Platform Size (mm) |

L2000/2500*W2000 |

L2000/2500*W2000 |

L2000/2500*W2000 |

L2000/2500*W2000 |

|

Operating Specifications and Technical Key Points of Hydraulic Disassembly Platform:

- The equipment adopts a one-button lifting control system. A short press of the start button triggers the automatic lifting program. After releasing the button, the platform descendes smoothly to the surface of the transport carrier relying on its own weight and then enters the positioning state.

- The power supply system complies with the international industrial safety voltage standard (380V/50Hz). In response to the parameter differences of power grids in various countries, this equipment supports personalized customization services for voltage/frequency/interface, and can be adapted to the mainstream international power specifications.

- The base construction should be carried out in accordance with the drawings, with positioning holes and wiring channels set up. The cable conduits should be precisely pre-embedded at the end axis position of the foundation pit. The Angle steel components should be fixed with anchor bolts welded on the inner side to ensure that the triangular support area of the foundation pit and the edge of the Angle steel achieve structural interlocking.

- The foundation structure is implemented with a layered compaction process: the bottom layer is filled with graded sand and gravel bedding, and the surface layer is poured with concrete. The side walls of the foundation pit must be rigidly connected to the main structure of the building with bidirectional steel mesh sheets. During the construction process, the gaps of the components need to be monitored in real time.

- The concrete pouring is carried out in two stages: For the first pouring, the positioning space of the Angle steel base needs to be reserved and the anti-collision steel plates need to be pre-installed. After the structural strength meets the standard, the secondary pouring is carried out, and the permanent fixation of the Angle steel components is achieved through the vibration process.

- The equipment is subject to a dedicated personnel and position management system. Operators must be certified and meet the following qualification requirements: normal visual and auditory functions, rapid response capabilities, and a high sense of safety responsibility.

- Before operation, the site must be cleared and a warning area set up. During the operation cycle of the equipment, it is strictly prohibited to carry people or goods. No obstacles should be piled up or cross-operation should be carried out within a 3-meter radius of the platform's movement.

Real Order

Hot Tags: hydraulic disassembly dock bridge platform, Portable Man Lift, Mast Aerial Work Platform, 60 Ft Articulating Aluminum Boom Lift, Aerial Work Platform, Cheap Residential Lift Elevator, Push Around Scissor Lift