Shandong Cathay Machinery Co., Ltd. is one of the most experienced manufacturers and suppliers of hydraulic loading dock leveler in China. We warmly welcome you to buy discount hydraulic loading dock leveler for sale here from our factory. Quality products and reasonable price are available.

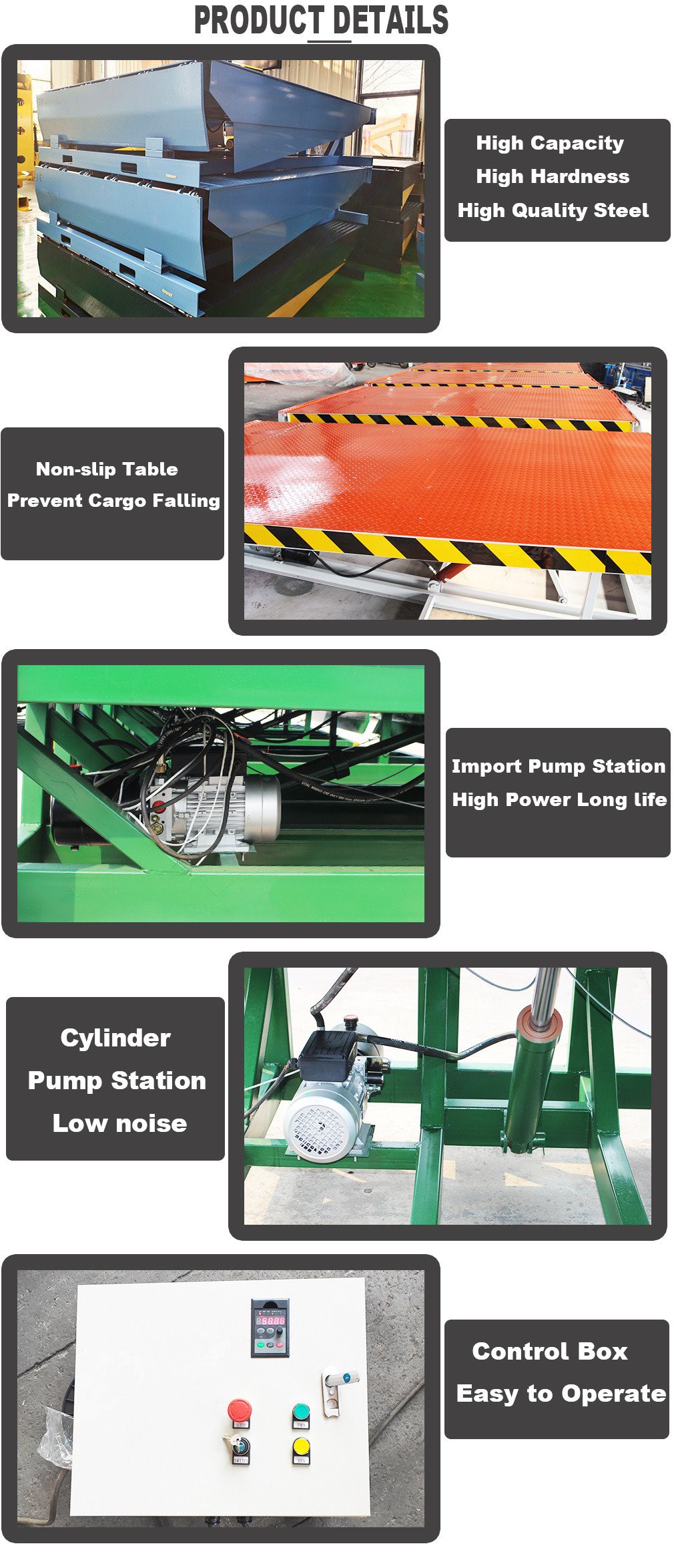

The CATHAYLIFT Hydraulic Dock Leveler is equipped with safety struts. During maintenance, maintenance, and cleaning, the adjustment plate is supported by struts, which are more secure and reliable. Colleagues install anti-collision rubber blocks, and the four outer corners of the anti-collision block are arc-shaped and the bolt holes are all deeply embedded.

Model No. | CDR-6 | CDR-8 | CDR-10 | CDR-12 | |

Load Capacity (t) | 6 | 8 | 10 | 12 | |

Platform Size (mm) | L2000/2500*W2000 | L2000/2500*W2000 | L2000/2500*W2000 | L2000/2500*W2000 | |

Features&Advantages:

● Working principle The operation of the adjustment plate is extremely simple, just press the button, and the adjustment plate will rise automatically; release the button, the adjustment plate will drop on the car by its own weight and it can be used.

● The power supply conforms to the safety standard 380V/50Hz. Due to the inconsistent voltage, frequency, and plug used in different countries, we can customize according to different needs.

● When installing the equipment, you need to dig a blank hole and lead hole first. The lead hole is used to pre-embed the wire, and the wire hole is reserved at the center of the tail of the pit. The rivets need to be welded to the inner surface of the angle steel, and the triangles of the pit need to be edged with the angle steel.

● The bottom layer of the pit needs to be laid with a layer of crushed sand, and the upper layer needs to be laid with reinforced concrete. The two sides of the pit must be firmly connected with the mesh steel bar and the special steel mesh for civil construction. Pay attention to the gap.

● After the mesh reinforcement of the equipment pit is completed, it needs to be poured with cement, the angle steel position should be reserved, and the thick steel plate of the collision block should be pre-buried. Finally, the secondary pouring is carried out, and the angle steel can be fixed.

● The loading and unloading platform must be operated by the designated operator, and others are not allowed to start it without authorization. Operators must have good vision, hearing, adequate judgment, and a strong sense of responsibility.

● Before operating, you must tell others to stay away from the platform. During the operation of the platform, no goods or people are allowed to be placed on the platform, and no goods or personnel are allowed to block the platform in the operating area.

Real Order

Hot Tags: hydraulic loading dock leveler, Forklift Ramp, Dockleveller Supplies, Dock High Ramp, Mobile Industrial Loading Ramps, Loading Dock Leveler, Loading Platform