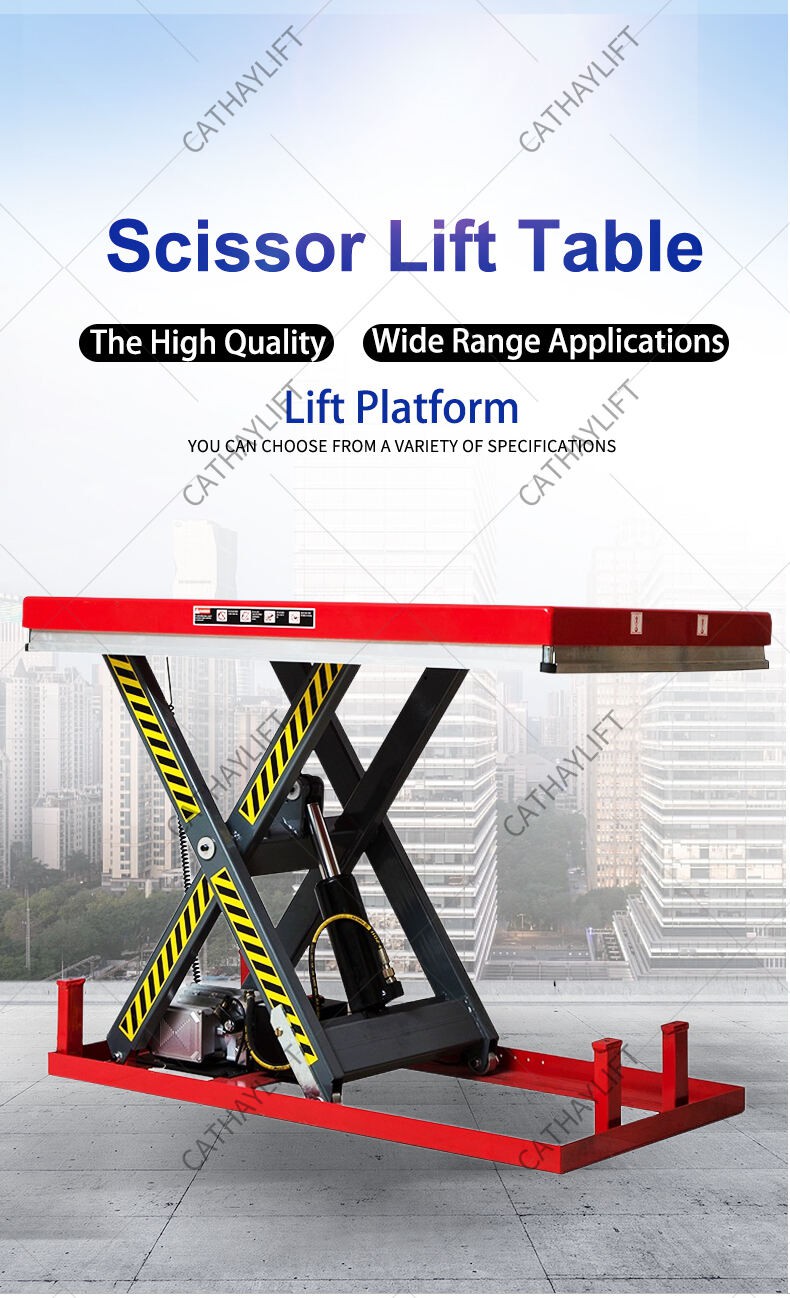

Shandong Cathay Machinery Co., Ltd. is one of the most experienced manufacturers and suppliers of small scissor lift table in China. We warmly welcome you to buy discount small scissor lift table for sale here from our factory. Quality products and reasonable price are available.

Small Scissor Lift Table

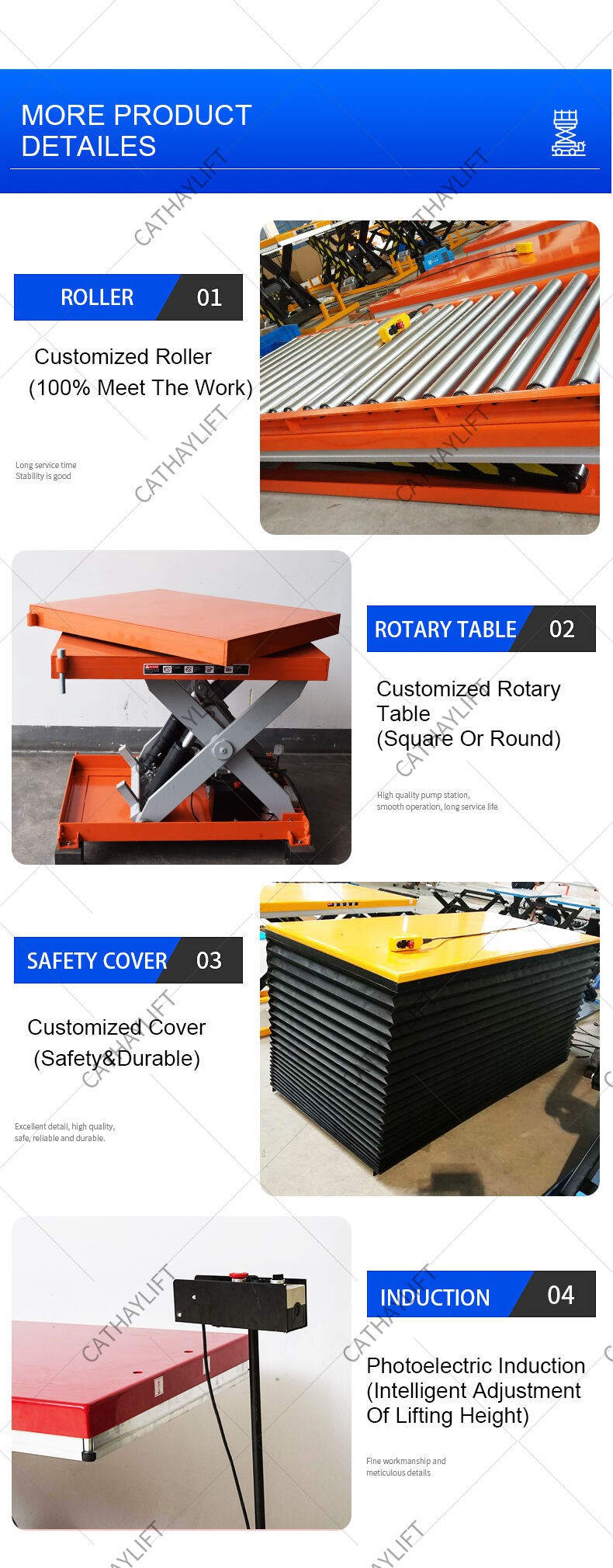

The small scissor lift table of this non-standard customized lifting platform can be modified to include features such as table angle flip, table rotation, table telescopic, table ball type, table roller type, stage type, U-shaped table type, organ cover, fixed track walking type, and more to suit the specific needs of users. Its table size, lifting height, load volume, and load tonnage can be customized for non-standard requirements based on the customer's site size and operational needs.

Products Details

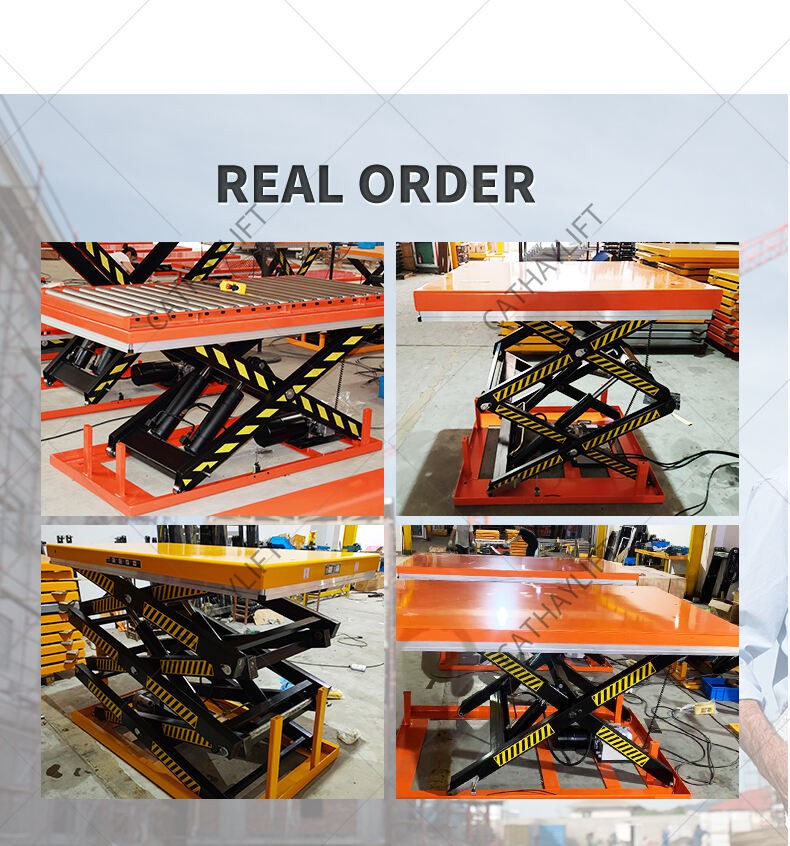

The small scissor lift table is known for its smooth and fast lifting capabilities, ability to handle heavy loads, and large working surface. With its customizable features, the lifting platform can meet diverse needs and ensure efficient and safe operations.

Advantages:

The small scissor lift table is an impressive piece of equipment that is packed with features designed to enhance its functionality, safety, and durability.

One of the standout features of this lift table is its surface treatment, which includes shot blasting and stoving varnish. This treatment not only gives the lift table a sleek, professional look, but it also provides excellent anti-corrosion protection, ensuring that the lift table remains in top condition even with regular use.

The lift table's stability is also a key feature, thanks to its high-quality pump station. This pump station ensures that the lift table moves smoothly and without any wobbling, which is essential for safe and efficient operation. Additionally, the lift table's anti-pinch scissor design helps to prolong its lifespan, making it a worthwhile investment for any business.

Safety is a top priority with this lift table, which is why it comes equipped with heavy-duty cylinders that feature a drainage system and check valve. These features prevent the lift table from dropping suddenly in case of a hose burst, ensuring that operators and nearby personnel remain safe. Additionally, the pressure relief valve prevents the lift table from being overloaded, reducing the risk of accidents.

Another noteworthy safety feature is the aluminum safety sensor that is located under the platform. This sensor helps prevent pinching and other accidents that could occur during operation, adding an extra layer of protection for operators and bystanders alike.

The lift table is designed to meet both American standard ANSI/ASME and Europe standard EN1570, ensuring that it adheres to the highest safety and quality standards in the industry. It also has a safe clearance between the scissor, which prevents damage during operation.

Overall, this lift table is a top-quality piece of equipment that is both easy to operate and maintain. It stops at predetermined and accurate location points, ensuring that it can be used with precision and efficiency. Its robust construction, safety features, and stability make it a valuable addition to any business that requires lifting and moving heavy loads.

Safety:

Explosion-proof valves: These valves are designed to prevent explosions that could occur due to hydraulic fluid leaks or sparks from electrical components. They contain materials that can withstand high pressure and temperature and are often used in hazardous environments such as oil and gas refineries.

Spillover valve: This valve is used to prevent high pressure when the lift moves up. It is designed to automatically adjust the pressure to prevent damage to the lift or the load being lifted.

Emergency decline valve: This valve is used in emergency situations such as power outages or when the lift operator needs to quickly lower the platform. It can also be used to prevent damage or injury in case of malfunctioning equipment.

Overload protection locking device: This device is used to prevent dangerous overloading of the lift. It works by locking the lift in place if it exceeds its weight capacity, preventing it from moving and causing damage or injury.

Anti-dropping device: This device is designed to prevent the lift platform from falling due to equipment failure or other factors. It can be either mechanical or hydraulic and is often required by safety regulations.

Automatic aluminum safety sensor: This sensor is used to detect obstacles or other barriers that may be in the lift's path. It is designed to automatically stop the lift to prevent damage to the platform or injury to people in the vicinity.

Real Order

|

Model |

Load Capacity (KG) |

Self Height (MM) |

Max Platform Height (MM) |

Platform Size (MM) |

Lifting time (S) |

Net weight (KG) |

|

500kg Load Capacity |

||||||

|

C0501 |

500 |

180 |

950 |

610*916 |

17~22 |

160 |

|

C0502 |

500 |

200 |

1000 |

1200*600 |

20~25 |

120 |

|

C0503 |

500 |

200 |

1000 |

1200*800 |

20~25 |

130 |

|

C0504 |

500 |

200 |

1000 |

2000*800 |

20~25 |

240 |

|

1000KG Load Capacity |

||||||

|

C1000 |

1000 |

180 |

770 |

610*916 |

15~20 |

115 |

|

C1001 |

1000 |

205 |

1000 |

1300×820 |

20~25 |

160 |

|

C1002 |

1000 |

205 |

1000 |

1600×1000 |

20~25 |

186 |

|

C1003 |

1000 |

190 |

1010 |

1300*800 |

20~25 |

160 |

|

C1004 |

1000 |

240 |

1300 |

1700×850 |

30~35 |

200 |

|

C1005 |

1000 |

240 |

1300 |

1700×1000 |

30~35 |

210 |

|

C1006 |

1000 |

240 |

1300 |

2000×850 |

30~35 |

212 |

|

C1007 |

1000 |

240 |

1300 |

2000×1000 |

30~35 |

223 |

|

C1008 |

1000 |

240 |

1300 |

1700×1500 |

30~35 |

365 |

|

C1009 |

1000 |

240 |

1300 |

2000×1700 |

30~35 |

430 |

|

C1010 |

1000 |

305 |

1780 |

1300X820 |

35-45 |

210 |

|

C1011 |

1000 |

470 |

3000 |

1700x1000 |

35-45 |

450 |

|

2000KG Load Capacity |

||||||

|

C2001 |

2000 |

230 |

1000 |

1300×850 |

20~25 |

235 |

|

C2002 |

2000 |

205 |

1000 |

2500*820 |

20~25 |

300 |

|

C2003 |

2000 |

230 |

1050 |

1600×1000 |

20~25 |

268 |

|

C2004 |

2000 |

250 |

1300 |

1700×850 |

25~35 |

289 |

|

C2005 |

2000 |

250 |

1300 |

1700×1000 |

25~35 |

300 |

|

C2006 |

2000 |

250 |

1300 |

2000×850 |

25~35 |

300 |

|

C2007 |

2000 |

250 |

1300 |

2000×1000 |

25~35 |

315 |

|

C2008 |

2000 |

250 |

1400 |

1700×1500 |

25~35 |

415 |

|

C2009 |

2000 |

250 |

1400 |

2000×1800 |

25~35 |

500 |

|

C2010 |

2000 |

190 |

1010 |

1300*800 |

20~25 |

235 |

|

C2011 |

2000 |

350 |

1780 |

1300X850 |

35-45 |

295 |

|

4000KG Load Capacity |

||||||

|

C4000 |

4000 |

230 |

1000 |

2500*850 |

20~25 |

320 |

|

C4001 |

4000 |

240 |

1050 |

1700×1200 |

30~40 |

375 |

|

C4002 |

4000 |

240 |

1050 |

2000×1200 |

30~40 |

405 |

|

C4003 |

4000 |

300 |

1400 |

2000×1000 |

35~40 |

470 |

|

C4004 |

4000 |

300 |

1400 |

2000×1200 |

35~40 |

490 |

|

C4005 |

4000 |

300 |

1400 |

2200×1000 |

35~40 |

480 |

|

C4006 |

4000 |

300 |

1400 |

2200×1200 |

35~40 |

505 |

|

C4007 |

4000 |

350 |

1300 |

1700×1500 |

35~40 |

570 |

|

C4008 |

4000 |

350 |

1300 |

2200×1800 |

35~40 |

655 |

|

C4009 |

4000 |

400 |

2050 |

1700X1200 |

55-65 |

520 |

|

Max Platform Height≥3M |

||||||

|

C1011 |

1000 |

470 |

3000 |

1700x1000 |

35-45 |

450 |

|

C2012 |

2000 |

560 |

3000 |

1700x1000 |

50-60 |

750 |

|

C2013 |

2000 |

850 |

4200 |

2500*1500 |

70-80 |

900 |

|

C0401 |

400 |

600 |

4140 |

1700x1000 |

30-40 |

800 |

|

C0801 |

800 |

706 |

4210 |

1700x1000 |

70-80 |

858 |

|

Other |

||||||

|

C3001 |

3000 |

220 |

1010 |

1300*800 |

20~25 |

350 |

|

C8000 |

8000 |

240 |

1050 |

3000*1200 |

20~25 |

370 |

Hot Tags: small scissor lift table, Electric Lift Table, Standard Hydraulic Three Scissor Lift, Mobile Scissor Lift With Motorized Device, Mobile Electric Scissor Lift Platform, heavy duty hydraulic scissor lift table, Scissor Table Lifter