Shandong Cathay Machinery Co., Ltd. is one of the most experienced manufacturers and suppliers of electric car mover robot in China. We warmly welcome you to buy discount electric car mover robot for sale here from our factory. Quality products and reasonable price are available.

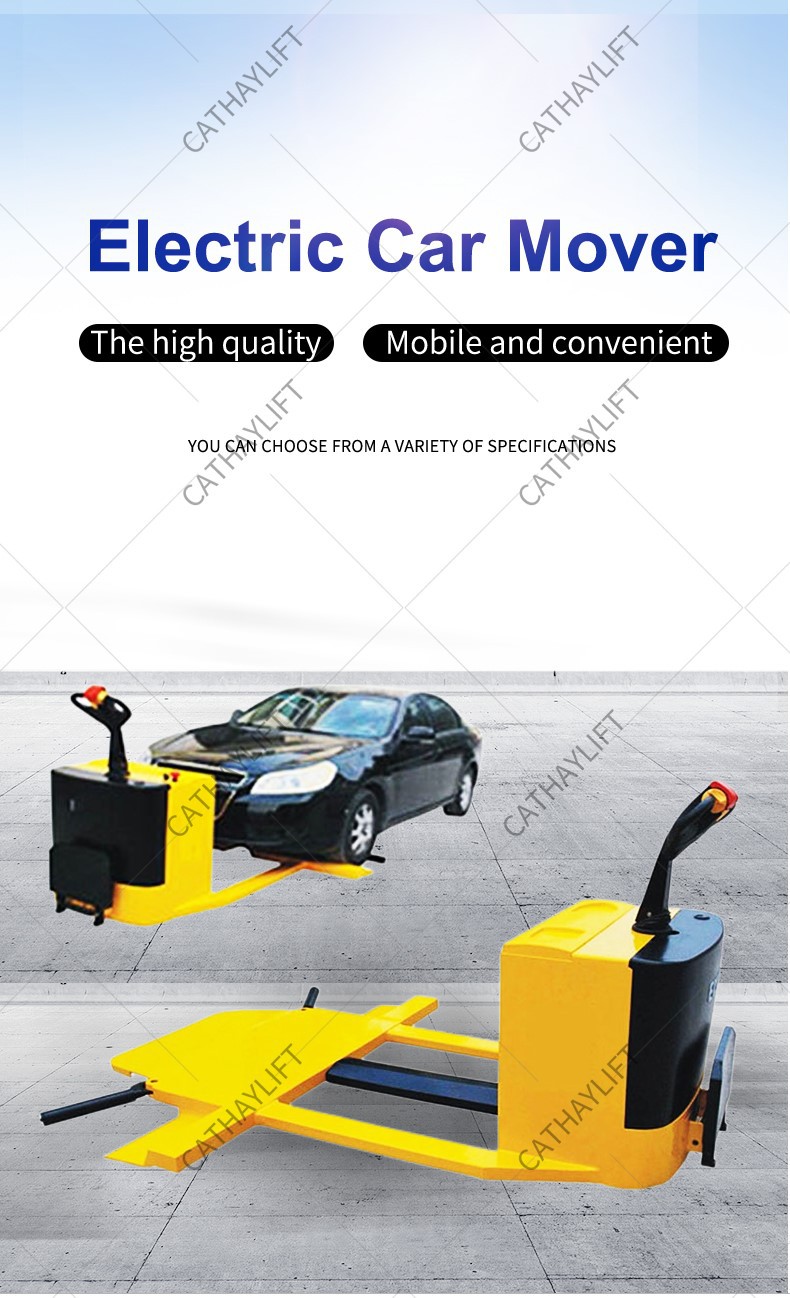

The Electric Car Mover Robot

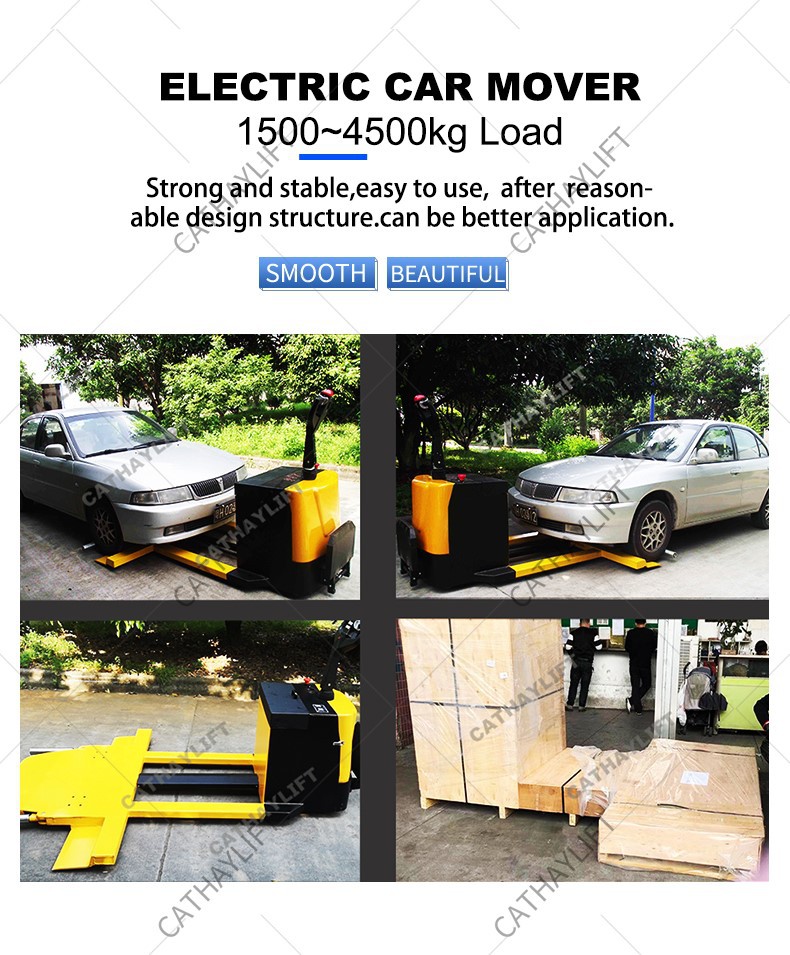

An electric car mover robot is a specially designed robot used for automobile manufacturers, parking lots, and exhibition halls. It is used for shifting and transporting motor vehicles without ignition. It uses an advanced electronic stepless speed regulation system, electro-hydraulic lifting, and has an electric stepless speed regulation system. It is also equipped with a high-performance power battery and a portable charger, making it suitable for small motor vehicles in residential parking lots and underground parking lots.

Advantages:

Advantages of the electric car mover robot include improved handling and transportation of motor vehicles, optional foldable standing pedals for convenience and reduced labor intensity, and a stepless speed regulation electric walking mode with high-power DC motor hydraulic station, and ergonomic handle. This makes the electric car mover robot ideal for modern logistics handling requirements, such as loading and unloading, handling, and shifting of small motor vehicles.

Safe Operation& Maintenance

To ensure the safe operation and maintenance of the electric car mover robot, the following procedures should be followed:

- The vehicle should be operated by a special person who abides by safety operation rules, and it should be used in a clean working environment.

- The operator's vision must be good, and there must be enough space around the car for other people or other vehicles. The operating speed must match the surrounding environment.

- The operator should not ride, sit on the car, or carry people, and should use as little emergency braking, multiple starts, and high-speed turns as possible to reduce vehicle damage and accidental injuries.

- It is not allowed to adjust and increase the pressure of the relief valve of the hydraulic station, and it is not allowed to lift goods that exceed the rated load.

- When driving on a slope, the cargo must be checked for looseness, and the car must be driven slowly and never turned on the slope or run diagonally up and down.

- The capacity of the battery should be checked carefully before use, and battery fluid should be added to the battery pack if necessary.

- The oil pipe joints should be checked for leaks, and the hydraulic oil capacity in the oil tank should be checked frequently and replenished as necessary.

- The electrical system should be cleaned regularly to prevent short-circuit damage of electrical appliances, and the lead wires of each connector should be checked for damage.

- The oil pump, carbon brushes of the drive motor, and commutator should be checked regularly.

- The brake should be adjusted regularly.

- The battery charging time is generally 6-8 hours. During the initial charging, the current is important, and it should be reduced as the battery approaches full charge.

- When charging the battery, make sure that the charger is connected to a grounded power socket and that the charging voltage matches the battery voltage. The charging process should be carried out in a well-ventilated area, away from any sources of heat or open flames. It is important to monitor the charging process and to disconnect the charger once the battery is fully charged.

- Before starting the Electric Car Mover Robot, it is important to ensure that all safety features are in place and functioning properly. This includes checking the brakes, lights, horn, and emergency stop button. Any defects or malfunctions should be reported to the appropriate personnel and repaired before operating the vehicle.

- The Electric Car Mover Robot should only be used on flat and smooth surfaces. It should not be operated on steep slopes, stairs, or uneven terrain. If the vehicle needs to be transported up or down a slope, it should be done with caution and at a slow speed.

- The operator should always wear appropriate personal protective equipment (PPE) such as a hard hat, safety glasses, and work boots. It is also recommended to wear gloves when handling the controls to avoid blisters or injuries.

- The Electric Car Mover Robot should never be overloaded beyond its rated capacity. The weight of the load should be evenly distributed on the forks and should not exceed the maximum weight limit. Overloading the vehicle can cause damage to the motor, hydraulic system, and other components, and can also pose a safety risk to the operator and others nearby.

- Regular maintenance and inspections are necessary to ensure the safe and efficient operation of the Electric Car Mover Robot. This includes checking and changing the hydraulic oil, inspecting the brakes and tires, tightening loose bolts and nuts, and cleaning and lubricating moving parts. Any repairs or replacements should be done by qualified personnel.

By following these guidelines and taking proper care of the Electric Car Mover Robot, it can provide safe and reliable transportation and handling of motor vehicles in a variety of settings.

|

Model |

ECM-1500 |

ECM-2500 |

ECM-3500 |

ECM-4500 |

|

Loading Capacity |

1500KG |

2500KG |

3500KG |

4500KG |

|

Battery |

2x12V/100AH |

2x12V/210AH |

2x12V/210AH |

2x12V/280AH |

|

Charger |

24V/15A |

24V/30A |

24V/30A |

24V/40A |

|

Driving Motor |

DC24V/700W |

DC24V/1200W |

DC24V/1500W |

DC24V/1500W |

|

Lifting Motor |

24V/1300W |

24V/2000W |

24V/2000W |

24V/2000W |

|

Climbing Capacity(unloaded) |

10% |

10% |

10% |

10% |

|

Climbing Capacity(loaded) |

5% |

5% |

5% |

5% |

|

Materials |

Steel panel 6mm |

|||

|

Battery Power Indicator |

Yes |

|||

|

Driving Wheel |

PU |

|||

|

Driving speed |

0~6.5Km/h E-CVT |

|||

|

Lifting height |

115mm |

|||

|

Braking type |

Electromagnetic braking |

|||

|

Street Request |

2000mm can move Forward and Backward |

|||

Hot Tags: electric car mover robot, Portable Electric Car Mover, Electric Hydraulic Car Mover, Electric Car Mover