Shandong Cathay Machinery Co., Ltd. is one of the most experienced manufacturers and suppliers of electric vehicle mover in China. We warmly welcome you to buy discount electric vehicle mover for sale here from our factory. Quality products and reasonable price are available.

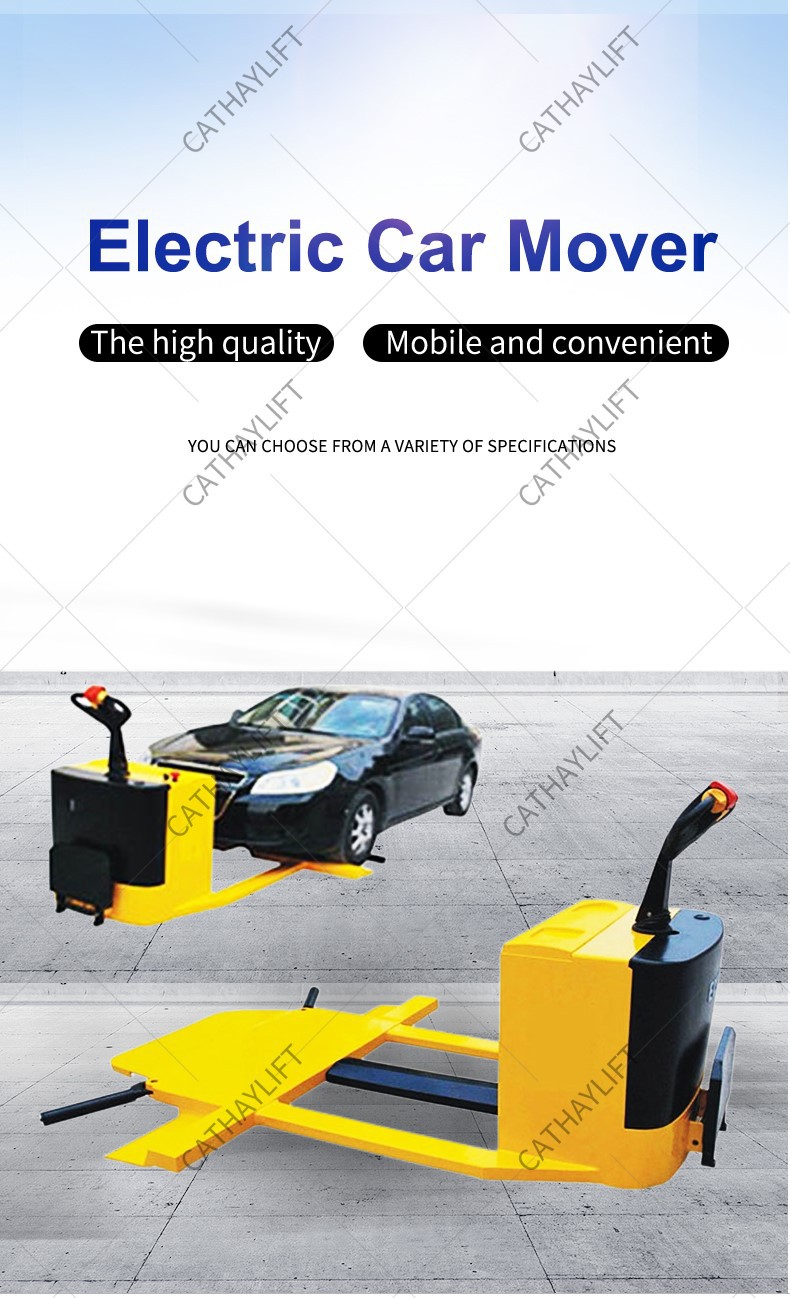

Electric Vehicle Mover

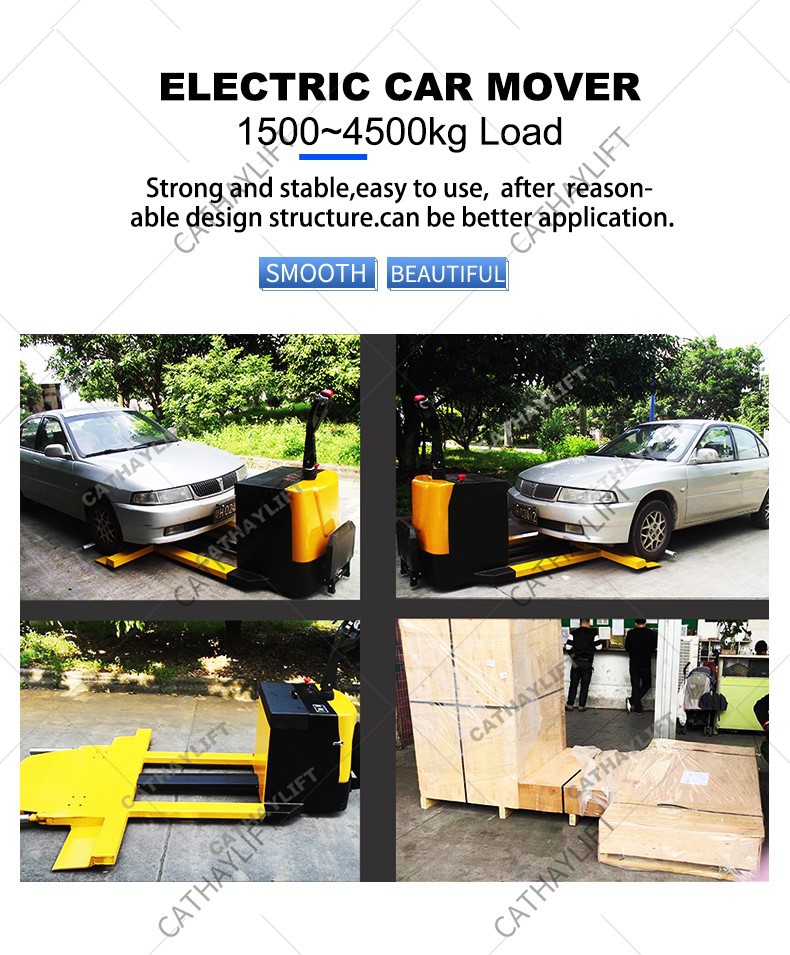

Electric Vehicle Mover is a material-handling product specially designed to facilitate the movement of vehicles. The product is controlled by a control handle. It is divided into four models with different loads according to different vehicles, which can meet the needs of most vehicles. Widely used in parking places, automobile production plants, or places for vehicle maintenance.

|

Model |

ECM-1500 |

ECM-2500 |

ECM-3500 |

ECM-4500 |

|

Loading Capacity |

1500KG |

2500KG |

3500KG |

4500KG |

|

Battery |

2x12V/100AH |

2x12V/210AH |

2x12V/210AH |

2x12V/280AH |

|

Charger |

24V/15A |

24V/30A |

24V/30A |

24V/40A |

|

Driving Motor |

DC24V/700W |

DC24V/1200W |

DC24V/1500W |

DC24V/1500W |

|

Lifting Motor |

24V/1300W |

24V/2000W |

24V/2000W |

24V/2000W |

|

Climbing Capacity(unloaded) |

10% |

10% |

10% |

10% |

|

Climbing Capacity(loaded) |

5% |

5% |

5% |

5% |

|

Materials |

Steel panel 6mm |

|||

|

Battery Power Indicator |

Yes |

|||

|

Driving Wheel |

PU |

|||

|

Driving speed |

0~6.5Km/h E-CVT |

|||

|

Lifting height |

115mm |

|||

|

Braking type |

Electromagnetic braking |

|||

|

Street Request |

2000mm can move Forward and Backward |

|||

Maintenance of The Battery:

1. Check the liquid level every other month. If it drops, please fill it up with distilled or purified water. The surface of the battery, connecting wires, and bolts should always be kept clean and dry. If there is acid, it should be wiped off with cotton gauze dipped in an alkali solution, then rinsed with clean water and dried. During the cleaning process, absolutely do not allow the alkaline solution to enter the battery.

2. The connection of the battery must be kept in good contact, so as not to cause sparks to cause the battery to explode or the pole to burn out.

3. The battery should avoid overcharging, over-discharging, strong charging, and insufficient charging. Failure to do so will shorten battery life.

4. Do not allow any harmful impurities to fall into the battery. The instruments and utensils used to measure the concentration density, temperature and liquid level of the electrolyte should be kept clean to avoid bringing impurities into the battery.

5. Do not place any conductive items on the battery cover, so as not to cause an external short circuit of the battery.

6. After the battery is discharged, it should be charged in time. The maximum interval should not exceed 24 hours.

7. When the battery is in use, if there is a lagging battery, the cause should be found in time and repaired immediately. If it cannot be repaired, a new battery should be replaced.

8. The temperature of the water and sulfuric acid solution injected into the battery should be between 10-40ºC, not too high or too low. If the battery temperature is higher than 45°C during charging, stop charging immediately and wait for the liquid temperature to drop before proceeding.

9. Fireworks are strictly prohibited in the charging room to avoid hydrogen explosion accidents. There should be good ventilation in the charging room, and the temperature should not be lower than 15ºC.

10. When the battery is in use, there will often be unbalanced voltage, density, and capacity. Balanced charging can not only prevent the occurrence of the above phenomena but also prevent the generation of backward batteries so that each battery can achieve a balanced and consistent state during use. If one of the following situations occurs, equalization charging should be carried out:

a. The discharge voltage often drops below the termination voltage; b. The discharge current value is often too large;

c. Failure to recharge in time after discharge; d. When the electrolyte is mixed with minor harmful impurities;

e. When the battery is often insufficiently charged or has not been used for a long time; f. After the electrode group is taken out for inspection or to remove sediment.

Balanced charging method: first charge the battery normally, after the charging is completed, let it stand for 1 hour, and then continue charging with the current value of the second stage of normal charging, until violent bubbles are generated, temporarily stop charging for 1 hour, and repeat this several times, until the voltage and density remain the same, and after an interval of recharging, violent air bubbles will be generated immediately.

During equalization charging, the voltage, density, and electrolyte temperature of each battery should be measured and recorded; before charging is completed, the density and liquid level of the electrolyte should be adjusted to meet the requirements.

The main reason for most accidents is the negligence of safety operation regulations:

For the sake of safety, when the locomotive is not in use for a long time, the power switch of the pallet truck should be checked and turned off, and the power plug connection between the battery and the electric scooter should be disconnected. Put the battery plug cable in the appropriate place according to the actual situation. It is strictly forbidden to lift the drive motor to idle at high speed and attach the "No Operation" notice to be placed in a place where anyone can see when using the car at any time.

Be sure to keep the electrical circuit plug-in boards and components in the locomotive clean to prevent possible short-circuit damage to electronic components due to dirty electric control boards. When cleaning, please use high-pressure air and brush to clean gently.

For locomotives in use, the hydraulic oil may be hot, so be careful of burns caused by hot hydraulic oil. When repairing and maintaining, the power supply should be cut off to prevent unnecessary short circuits of circuit boards and electronic components by ornaments, rings, watches, and other items on the body.

Hot Tags: electric vehicle mover, Electric Car Mover, Portable Electric Car Mover, Electric Hydraulic Car Mover