Shandong Cathay Machinery Co., Ltd. is one of the most experienced manufacturers and suppliers of table lifter in China. We warmly welcome you to buy discount table lifter for sale here from our factory. Quality products and reasonable price are available.

CATHAYLIFT Table lifter is a stationary transport equipment that lifts goods from one height to another. Due to the weight, volume, safety and stability of the objects to be lifted, it is often used as a special hydraulic lifting platform product for transporting goods between floors of buildings. Its main function is to carry goods up and down between various working floors; It is mostly used for material lifting and car lifting, etc.

Model | Load Capacity(KG) | Self Height | Max Platform Height(MM) | Platform Size(MM) | Lifting time | Net weight |

500kg Load Capacity | ||||||

C0501 | 500 | 180 | 950 | 610*916 | 17~22 | 160 |

C0502 | 500 | 200 | 1000 | 1200*600 | 20~25 | 120 |

C0503 | 500 | 200 | 1000 | 1200*800 | 20~25 | 130 |

C0504 | 500 | 200 | 1000 | 2000*800 | 20~25 | 240 |

1000KG Load Capacity | ||||||

C1000 | 1000 | 180 | 770 | 610*916 | 15~20 | 115 |

C1001 | 1000 | 205 | 1000 | 1300×820 | 20~25 | 160 |

C1002 | 1000 | 205 | 1000 | 1600×1000 | 20~25 | 186 |

C1003 | 1000 | 190 | 1010 | 1300*800 | 20~25 | 160 |

C1004 | 1000 | 240 | 1300 | 1700×850 | 30~35 | 200 |

C1005 | 1000 | 240 | 1300 | 1700×1000 | 30~35 | 210 |

C1006 | 1000 | 240 | 1300 | 2000×850 | 30~35 | 212 |

C1007 | 1000 | 240 | 1300 | 2000×1000 | 30~35 | 223 |

C1008 | 1000 | 240 | 1300 | 1700×1500 | 30~35 | 365 |

C1009 | 1000 | 240 | 1300 | 2000×1700 | 30~35 | 430 |

C1010 | 1000 | 305 | 1780 | 1300X820 | 35-45 | 210 |

C1011 | 1000 | 470 | 3000 | 1700x1000 | 35-45 | 450 |

2000KG Load Capacity | ||||||

C2001 | 2000 | 230 | 1000 | 1300×850 | 20~25 | 235 |

C2002 | 2000 | 205 | 1000 | 2500*820 | 20~25 | 300 |

C2003 | 2000 | 230 | 1050 | 1600×1000 | 20~25 | 268 |

C2004 | 2000 | 250 | 1300 | 1700×850 | 25~35 | 289 |

C2005 | 2000 | 250 | 1300 | 1700×1000 | 25~35 | 300 |

C2006 | 2000 | 250 | 1300 | 2000×850 | 25~35 | 300 |

C2007 | 2000 | 250 | 1300 | 2000×1000 | 25~35 | 315 |

C2008 | 2000 | 250 | 1400 | 1700×1500 | 25~35 | 415 |

C2009 | 2000 | 250 | 1400 | 2000×1800 | 25~35 | 500 |

C2010 | 2000 | 190 | 1010 | 1300*800 | 20~25 | 235 |

C2011 | 2000 | 350 | 1780 | 1300X850 | 35-45 | 295 |

4000KG Load Capacity | ||||||

C4000 | 4000 | 230 | 1000 | 2500*850 | 20~25 | 320 |

C4001 | 4000 | 240 | 1050 | 1700×1200 | 30~40 | 375 |

C4002 | 4000 | 240 | 1050 | 2000×1200 | 30~40 | 405 |

C4003 | 4000 | 300 | 1400 | 2000×1000 | 35~40 | 470 |

C4004 | 4000 | 300 | 1400 | 2000×1200 | 35~40 | 490 |

C4005 | 4000 | 300 | 1400 | 2200×1000 | 35~40 | 480 |

C4006 | 4000 | 300 | 1400 | 2200×1200 | 35~40 | 505 |

C4007 | 4000 | 350 | 1300 | 1700×1500 | 35~40 | 570 |

C4008 | 4000 | 350 | 1300 | 2200×1800 | 35~40 | 655 |

C4009 | 4000 | 400 | 2050 | 1700X1200 | 55-65 | 520 |

Max Platform Height≥3M | ||||||

C1011 | 1000 | 470 | 3000 | 1700x1000 | 35-45 | 450 |

C2012 | 2000 | 560 | 3000 | 1700x1000 | 50-60 | 750 |

C2013 | 2000 | 850 | 4200 | 2500*1500 | 70-80 | 900 |

C0401 | 400 | 600 | 4140 | 1700x1000 | 30-40 | 800 |

C0801 | 800 | 706 | 4210 | 1700x1000 | 70-80 | 858 |

Other | ||||||

C3001 | 3000 | 220 | 1010 | 1300*800 | 20~25 | 350 |

C8000 | 8000 | 240 | 1050 | 3000*1200 | 20~25 | 370 |

Please Note: If the standard models can not meet your requirements, please ask us to customiZE it for you.

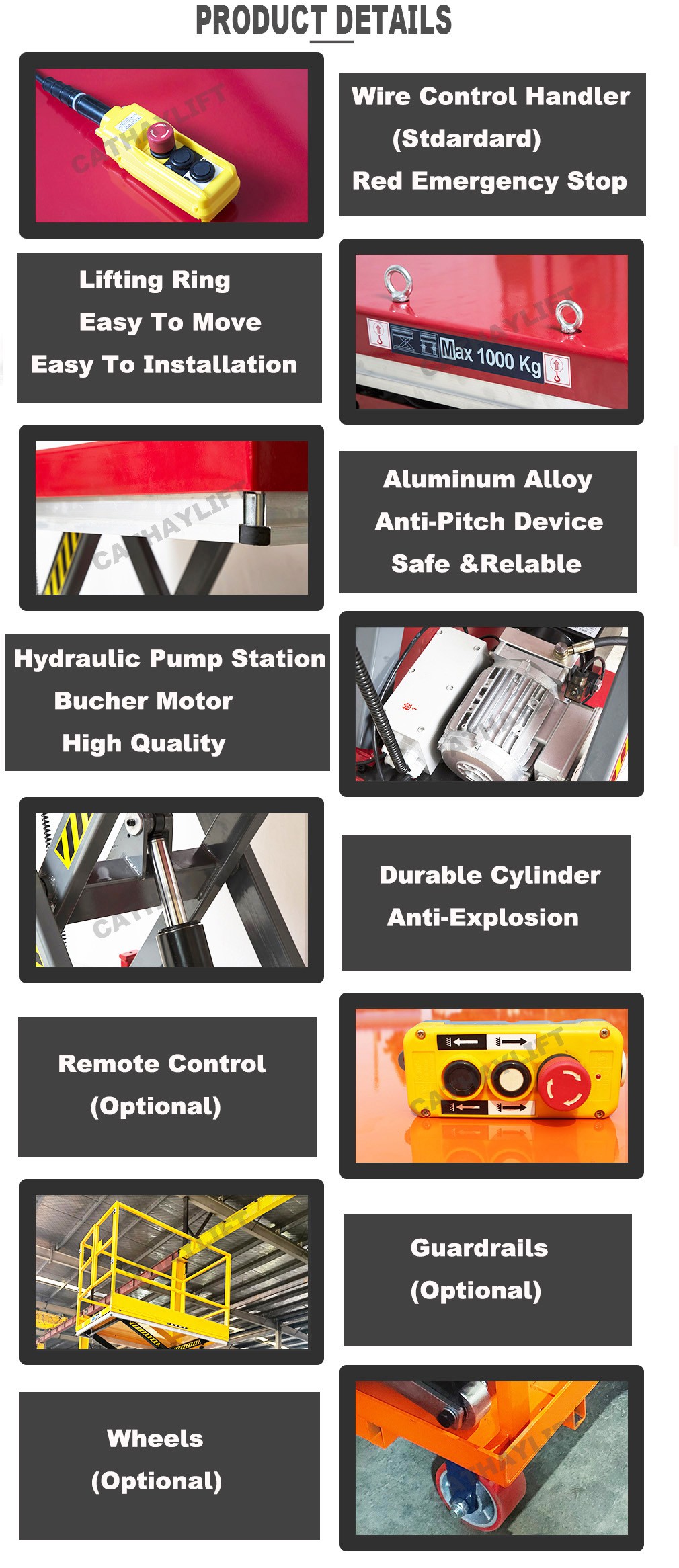

Product Details

Installation:

The Table Lift can be mounted on the ground or in a pit (so that the device is flush with the ground at its lowest point).

If installed in a pit:

● According to the requirements of the drawings, make the pit, the embedded parts are flush with the ground of the pit, CATHAYLIFT will design different drawings for customers according to the different products of each product.

● Adjust the upper stroke: Raise the platform to the designated position, confirm that it is in good condition, and install the limit switch.

● Weld the guide wheels on both sides of the platform (inside of the four corners). Then place the guide rail (channel steel) perpendicular to the guide wheel position on both sides of the platform, and place the guide wheel (according to the method on the guide wheel photo) in the guide rail, so that the guide wheel can slide freely in the guide rail.

● Connect the power supply, start the device, and check whether the guide rail and the host are in good condition.

● Look for a professional electrician to install the control box, arrange the lines, and connect the lines according to CATHAYLIFT instructions.

● Fix the iron plate (the size of the iron plate can release the guide rail) with expansion screws at the bottom position where the guide rail is placed, then weld the guide rail on the iron plate, and at the same time connect the top to make it firm up and down. Place the platform of the freight elevator in the pit, adjust the platform to the level of the platform and the ground, and weld the bottom of the platform and the embedded parts firmly.

● Testing machine: During the lifting and lowering process of the elevator, the guide wheel must slide smoothly in the guide rail to make the platform rise and fall smoothly.

● Acceptance: After the test machine is completed, clean up the site and remove other sundries in preparation for use.

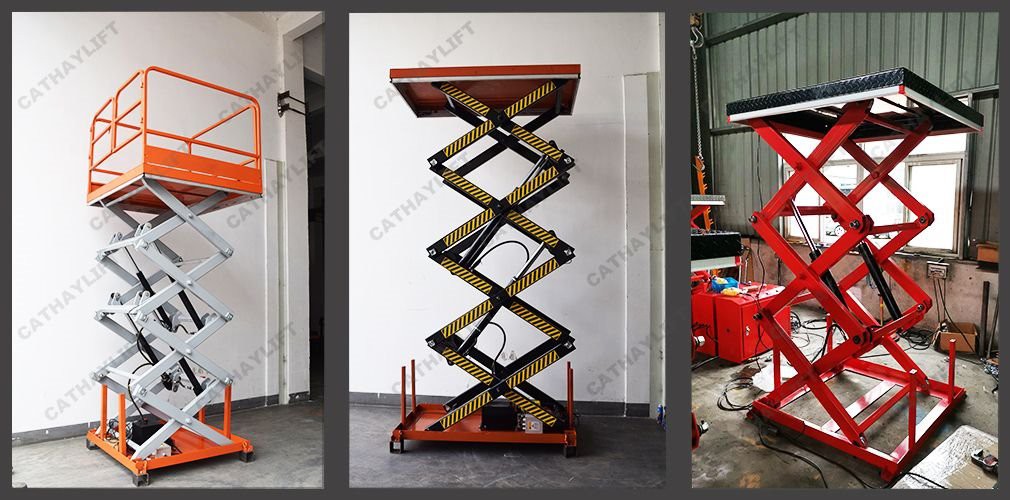

Real Order

Hot Tags: table lifter, Single Electric Scissor Lift, heavy duty hydraulic scissor lift table, Hydraulic Mobile Self propelled Scissor Lift, Table Lift, Industrial Hydraulic Electric Lift Table, Small Electric Automotive Scissor Lift