Shandong Cathay Machinery Co., Ltd. is one of the most experienced manufacturers and suppliers of telescopic self propelled boom lift in China. We warmly welcome you to buy discount telescopic self propelled boom lift for sale here from our factory. Quality products and reasonable price are available.

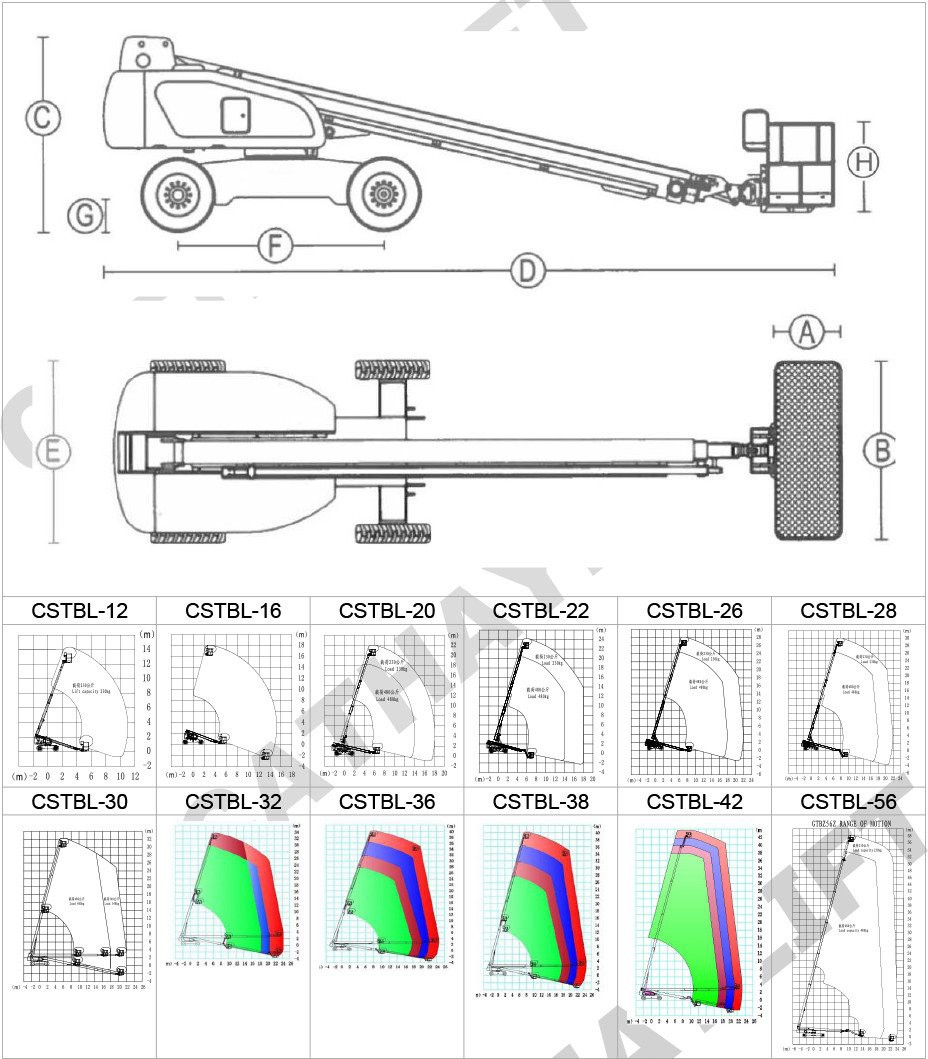

Model Type No. | CSTBL-12 | CSTBL-16 | CSTBL-20 | CSTBL-22 | CSTBL-26 | CSTBL-28 | CSTBL-30 | CSTBL-32 | CSTBL-36 | CSTBL-38 | CSTBL-42 | CSTBL-56 |

Max Working Height | 14.3m | 18.2m | 22.3m | 24.1 m | 28m | 30m | 32.4 m | 34 m | 38.64 m | 40.4 m | 44 m | 58m |

Max Platform Height | 12.3m | 16.2m | 20.3m | 22.1 m | 26m | 28m | 30.4m | 32 m | 36.64 m | 38.4 m | 42 m | 56m |

Max Working Radius | 10.5m | 15m | 18m | 18 m | 22m | 22m | 21.4 m | 21.4 m | 21.4 m | 21.4 m | 23 m | 26m |

Lift Capacity(restricted) | 480kg | 480kg | 480 kg | 480 kg | 480 kg | 480 kg | 480 kg | 480kg | 480 kg | 480 kg | 480 kg | 480kg |

Lift Capacity(non-restricted) | 230kg | 230kg | 230kg | 230 kg | 230kg | 230kg | 340 kg | 230 kg | 340 kg | 230 kg | 230 kg | 230kg |

Length( stowed) Ⓓ | 7.54m | 7.9m | 9.3m | 10.97 m | 11.55m | 13.5m | 13 m | 14.1 m | 13 m | 14.1 m | 13.3 m | 14.9m |

Width (stowed) Ⓔ | 2.29m | 2.39m | 2.49m | 2.49m | 2.5m | 2.5m | 2.5 m | 2.5 m | 2.5m | 2.5 m | 2.49 m | 5.1m |

Height(stowed) Ⓒ | 2.39m | 2.69m | 2.75m | 2.75 m | 2.83m | 2.83m | 3.08m | 3.08m | 3.08m | 3.08m | 3.28m | 3.6m |

Wheel Base Ⓕ | 2.45m | 2.45m | 3m | 3m | 3m | 3m | 3.66m | 3.66m | 3.96m | 3.96m | 3.96m | 5.6m |

Ground Clearance Ⓖ | 0.43m | 0.43m | 0.43m | 0.43 m | 0.43m | 0.43m | 0.43m | 0.43 m | 0.43m | 0.43m | 0.43 m | 0.43 m |

Platform SizeⒷ*Ⓐ | 1.83*0.76m | 1.83*0.76m | 1.83*0.76m | 1.83*0.76m | 2.44*0.91m | 2.44*0.91m | 2.44*0.91m | 2.44*0.91m | 2.44*0.91m | 2.44*0.91m | 2.44*0.91m | 2.44*0.91m |

Turning radius( inside) | 2.2 m | 2.66m | 3m | 3m | 3.59 m | 3.59 m | 2.74 m | 2.74 m | 3.13 m | 3.13 m | 3.13 m | 3.13m |

Turning Radius(outside) | 5.2 m | 5.66m | 3m | 3 m | 5.59 m | 5.59 m | 4.14 m | 4.14 m | 4.14 m | 4.14 m | 4.14 m | 7.6m |

Travel Speed(stowed) | 4.4 km/h | 4.4km/h | 4.4km/h | 4.4 km/h | 4.4 km/h | 4.4 km/h | 4.4 km/h | 4.4 km/h | 4.4 km/h | 4.4 km/h | 4.4 km/h | 4.4km/h |

Travel Speed(raised ) | 1.1 km/h | 1.1km/h | 1.1km/h | 1.1km/h | 1.1km/h | 1.1 km/h | 1.1km/h | 1.1km/h | 1.1km/h | 1.1km/h | 1.1km/h | 1.1km/h |

Grade Ability | 40% | 40% | 40% | 40% | 40% | 40% | 40% | 40% | 40% | 40% | 40% | 40% |

Solid Tire | 36×12-20 | 33×12-20 | 36×14-20 | 36×14-20 | 385/65-24 | 385/65-24 | 385/65-24 | 385/65-24 | 385/65-24 | 385/65-22.5 | 445/65-22.5 | 445/65-22.5 |

Platform Leveling | Automatic leveling | |||||||||||

Swing Speed | 0~1/3rpm | 0~1/3rpm | 0~1/3rpm | 0~1/3rpm | 0~1/3rpm | 0~1/3rpm | 0~1/3rpm | 0~1/3rpm | 0~1/3rpm | 0~1/3rpm | 0~1/3rpm | 0~1/3rpm |

Turn Table Swing | 360° Continuous | |||||||||||

Platform Rotation | ±80° | ±80° | ±80° | ±80° | ±80° | ±80° | ±80° | ±80° | ±80° | ±80° | ±80° | ±80° |

Fuel tank Capacity | 151L | 150L | 150L | 151 L | 151L | 151L | 151 L | 151 L | 151 L | 151L | 200L | 300L |

Total Weight | 7000kg | 10000kg | 12500kg | 13000 kg | 16500kg | 17000kg | 18500kg | 18650kg | 20120kg | 23000 kg | 23600kg | 27500kg |

Control Voltage | 12 V DC | 12 V DC | 12 V DC | 12 V DC | 12 V DC | 12V DC | 12 V DC | 12 V DC | 12 V DC | 12 V DC | 12 V DC | 24v |

Engine | Yanmar | Yanmar | Yanmar | Yanmar | Cummins | Cummins | Cummins | Cummins | Cummins | Cummins | Cummins | Cummins |

Loading/Shipping | 40GP | 40FR | 40FR OWOH | 40FR OWOH | 40FR OWOH | 40FR OOG | 40FR OOG | 40FR OOG | 40FR OOG | 40FR OOG | 40FR OOG | 40FR OOG |

Drive*Steering | 4WD*2WS / 4WD*4WS (WD: wheel drive,WS: wheel steering) | |||||||||||

Product technical performance advantages:

Full-scale gradient control - Full-scale gradient control of travel, boom lift, boom telescopic and rotating chassis makes the aerial work vehicle easy to position and operate more smoothly even in tight environments.

Driving Confirmation System - Enhances operator alertness and safety. When the arm turns over the non-steering wheel, the travel action cannot be operated and an indicator light on the platform operation panel is on, and the direction of travel movement may be opposite to that of the elephant movement. At this time, the driving confirmation switch must use the resume driving function to ensure that the operator knows the position of the arm and the correct driving direction of the handle.

Provides two seat belt hooks

Foot switch - control all function power. The foot must be off the foot switch to start the engine.

Automatic platform leveling - the platform automatically remains level when the boom angle changes. When the platform tilts more than 2 degrees, an alarm is issued, and when the platform tilts more than 3 degrees, the system cuts off the boom lift function and platform leveling function to protect the operator's safety.

All functions on the control panel are indicated by easy-to-understand pictograms.

Hydraulic system

Hydraulic components - drive pumps and travel motors are products of internationally renowned companies.

Full Pressure Hydraulic Filtration - Hydraulic filtration outside the pump (tank) and oil return filtration.

Closed-Cycle Hydraulic Ride Circuit—Provides Unmatched Power and Performance. This load sensing system automatically adjusts the pump output to maintain optimum performance. The travel system circuit uses state-of-the-art axial variable displacement piston pumps and piston travel motors.

Hydraulic System Modules - Provides reliability while improving maintainability and troubleshooting. Hydraulics are combined into four hydraulic modules for boom function, travel drive function, steering function, diverter function, platform function and auxiliary drive function, increasing reliability while reducing hoses, fittings and possible leaks. Diagnostics, troubleshooting and serviceability improve hydraulic and traditional piping systems. The module also features quick diagnostic connectors and spool interchangeability.

151L Hydraulic Tank - Provides a cooled hydraulic system to extend component life. The hydraulic oil tank has an oil level gauge, a temperature gauge, an absorption strainer, a return oil filter and a filter bypass gauge. This unit provides a cooled hydraulic system to extend component life, enhance corrosion resistance and improve monitoring system performance.

Hydraulic Oil Cooler - It operates in the return circuit of the hydraulic travel and is cooled by the motor fan. Additional hydraulic oil cooling is available when the machine is operating in hot climates or when the job site requires extended travel.

● Advanced harsh environment components

Provides the industry's best protection for machines operating in dusty, abrasive, spray and corrosive environments. It includes oil cylinder bellows sheath, arm sand scraping device, control box protection box, center turntable box, engine air intake pre-filtering device and other configurations to provide protection for the machine that performs sand washing and spraying operations.

● Igniter and repeated ignition protection system

Protect the engine flywheel ring gear and starter motor.

● Automatic engine shutdown

The engine automatically shuts off when the engine temperature is too high or the oil pressure is too low.

● The movable cover plate makes maintenance convenient

Maintenance personnel can easily access the internal structure of the machine.

● Pins and bushings

Easy maintenance and long life use. All moving pins use treated steel pins and self-lubricating bearings; no yellow grease is required. After periodic experiments, it can withstand 10 years of normal use.

● Control panel

In order to adapt to the use environment with more welding slag splash and dust, we have changed the panel of the touch-type mask to a steel panel.

● Length detector

A sensor is installed inside the tail of the boom to detect the extension length of the boom by detecting the oil cylinder, which not only reduces the occurrence of faults, improves the reliability, but also reduces the damage caused by human error.

Main Configuration:

Basket (side swing ±90°)

Proportional control handle:SAUER DANFOSS USA

Program controller: EPEC Finland

Length angle sensor: BPE Italy

Hydraulic valve:

Oil-control: Italy

Hydroforce: United States

Pump station:

SAUER DANFOSS USA

Salami Italy

Swing motor: HELAC USA

Walking reducer:

Brevini Italy

PMP Italy

Omni USA

Engine: Cummins USA

Real Order:

Hot Tags: telescopic self propelled boom lift, Telescopic Self Propelled Boom Lift, Self proplled Manned Sicssor Lift, Diesel Telescopic Boom Lift, Telescopic Boom Lift