Shandong Cathay Machinery Co., Ltd. is one of the most experienced manufacturers and suppliers of glass lifter suction cup in China. We warmly welcome you to buy discount glass lifter suction cup for sale here from our factory. Quality products and reasonable price are available.

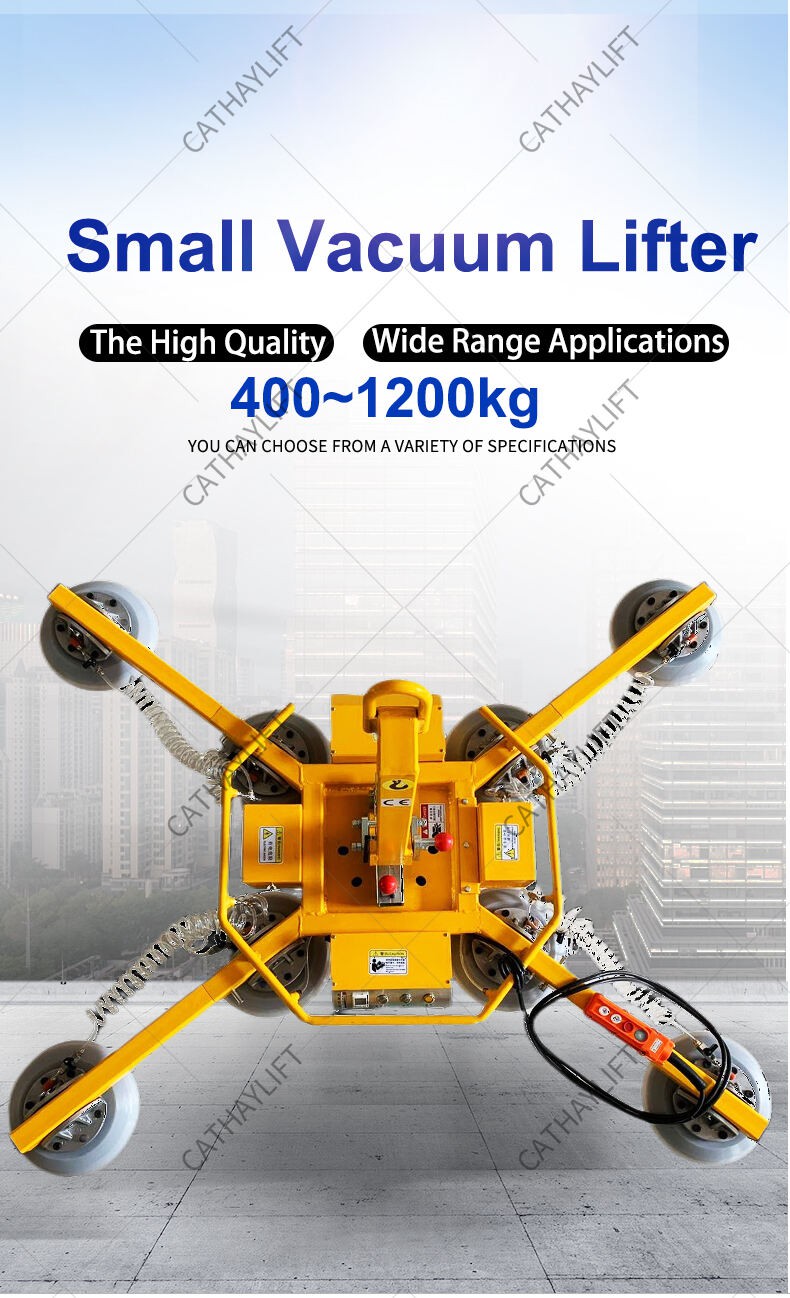

400kg~1200kg Glass Lifter Suction Cup

XC series glass panel lifting cups, renowned for their versatility and reliability in glass installation tasks. Designed for various applications including window, shower door, and glass table top installations, these suction cups are the go-to choice for professionals seeking efficiency and safety. With load capacities ranging from 400kg to 1200kg, they accommodate a wide range of project needs, ensuring secure handling of heavy glass panels. Trusted by professionals worldwide, the XC series combines robust construction with precise engineering, making it an indispensable tool for any glass installation project.

|

Model |

XC-S400 |

XC-S600 |

XC-S800 |

XC-S1000 |

XC-S1200 |

|

|

Lifting Capacity |

kg |

400 |

600 |

800 |

1000 |

1200 |

|

Cup Qty |

/ |

4 |

6 |

8 |

10 |

12 |

|

Rotation |

/ |

360°manual rotate |

||||

|

Tilting |

/ |

90° manual |

||||

|

Sucker Frame Size |

mm |

850*750*300 |

1800*900*300 |

1760*1460*300 |

1900*1600*300 |

1900*1600*300 |

|

Extension Bar Length |

mm |

500 |

||||

|

Overall Size |

mm |

1230*910*390mm, packed by wooden box |

||||

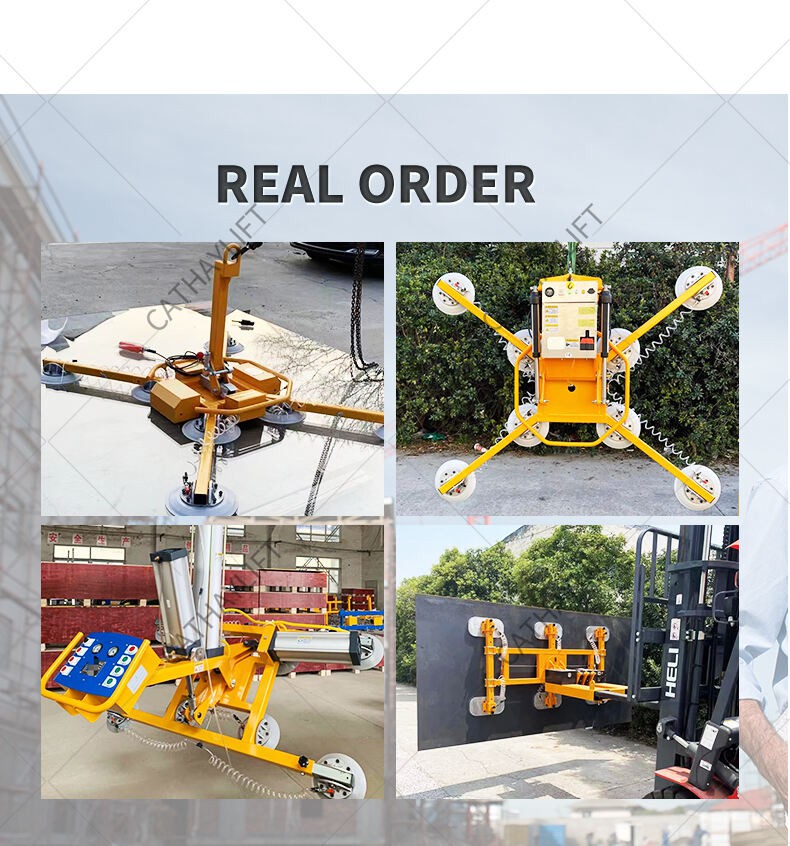

Products Details

Safety Instruction

Safety Precautions:

Always adhere to safety regulations and rules to prevent accidents. Example: Before starting any operation, ensure that all safety protocols are followed, including wearing appropriate protective gear and securing the work area.

Familiarize yourself with correct operating procedures and methods to ensure safe usage. Example: Before using the XC series glass panel lifting cups, thoroughly review the instruction manual to understand proper operating techniques.

Avoid modifying or damaging parts to prevent hazards and maintain machine performance and longevity. Example: Do not attempt to alter the suction cup mechanism or tamper with any components of the lifting device to prevent malfunctions and potential accidents.

Unauthorized personnel should not conduct repairs, and only original or manufacturer-recommended parts should be used for replacements. Example: In case of any malfunction, contact authorized service personnel for repairs and avoid using aftermarket parts to maintain the equipment's integrity.

Refrain from using the device in rainy conditions, and store it indoors after use to prevent electrical shorts. Example: After completing a glass installation task, store the glass lifting cups in a dry indoor location to avoid water damage and electrical hazards.

Operator Precautions:

Only trained personnel should operate the equipment, and individuals with certain health conditions or under the influence of alcohol should refrain from usage. Example: Pregnant women, individuals with physical discomfort, and those under 18 years old should not operate the glass lifting cups to ensure safety.

Conduct periodic inspections by professionals at least once every six months to ensure equipment integrity and functionality. Example: Schedule regular inspections by certified technicians to detect any potential issues and maintain optimal performance of the glass lifting cups.

Maintain a safe operating environment by keeping a minimum safety distance of 2 meters from bystanders and ensuring a smooth, debris-free working surface. Example: Before lifting heavy glass panels, clear the area of any obstacles and ensure that no individuals are within the designated working range.

Adhere to safety regulations during night operations, and provide adequate lighting for improved visibility. Example: Install proper lighting around the work area to enhance visibility and ensure safe operations during nighttime glass installation tasks.

Precautions for Machine Operation:

Confirm secure connections and tightened screws before usage, and avoid exceeding the approved load capacity of the machine. Example: Before lifting a heavy glass panel, inspect all connections and ensure that the lifting cups are securely attached within the specified weight limit.

Refrain from moving dirty or wet glass panels, and ensure stable attachment of suction cups before transportation. Example: Before transporting a glass panel, ensure that the suction cups are clean and firmly attached to prevent slipping or accidents during transit.

Avoid hoisting cargo carriers and leaving empty cups unattended, and prevent contact with people or obstacles during glass lifting operations. Example: Do not attempt to lift objects other than glass panels with the lifting cups, and always supervise the equipment to prevent accidents or damage to property.

Cease operation immediately in case of equipment failure to prevent accidents or further damage. Example: If any malfunction occurs during operation, stop using the glass lifting cups immediately and contact authorized personnel for assistance.

Hot Tags: glass lifter suction cup, Mobile Truck Loading Ramps, 500kg Aerial Electric Scissor Lift, Towable Man Lift, CE ISO Approved Boom Lift, Hydraulic Cargo Lift, Hydraulic Steering Mini Self Propelled Scissor Lift