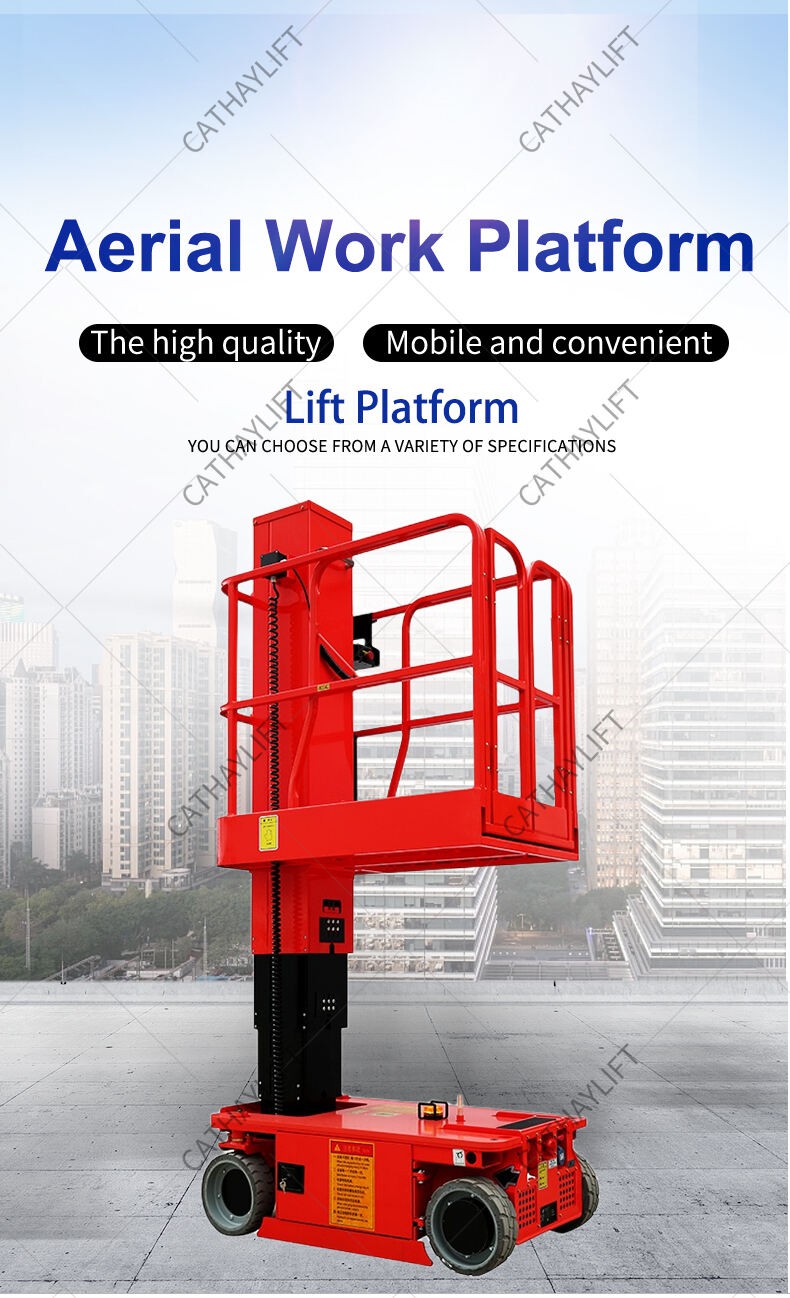

Shandong Cathay Machinery Co., Ltd. is one of the most experienced manufacturers and suppliers of mewp access in China. We warmly welcome you to buy discount mewp access for sale here from our factory. Quality products and reasonable price are available.

3.6m~6m 227kg Mewp Access

MEWP access platforms are highly versatile and efficient tools that provide a safe and secure way to work at lower heights. With their compact size, AC motor, and straight elevation, these platforms are ideal for use in tight indoor and outdoor spaces where traditional ladders or scaffolds would be impractical or unsafe.

|

Model Type No. |

CSTAR-3600 |

CSTAR-4800 |

CSTAR-6000 |

|

Max.Platform Height |

3.6m |

4.8m |

6m |

|

Max Working Height |

5.6m |

6.8m |

8m |

|

Load Capacity |

227kg |

159kg |

|

|

Extendable platform capacity |

114kg |

||

|

Platform Size |

1.3x0.7m |

||

|

Extendable Platform Length |

0.51m |

||

|

Wheel Base |

1.04m |

||

|

Inner Turning Radius |

0m |

||

|

Outer Turning Radius |

1.4m |

||

|

Travel Speed(Stowed) |

4km/h |

||

|

Travel Speed(Raised) |

1.1km/h |

||

|

Up/down Speed |

31/32sec |

41.5/42sec |

52/53sec |

|

Grade Ability |

25% |

||

|

Drive Tires |

305X100mm |

||

|

Drive Motors |

2X24VDC/0.5KW |

||

|

Lifting Motor |

24DC/1.3KW |

||

|

Battery |

2X12V/100AH |

||

|

Charger |

24V/15A |

||

|

Weight |

810kg |

980kg |

1060kg |

Products Details

Advantages

MEWP access platforms are highly versatile and efficient tools that provide a safe and secure way to work at lower heights. With their compact size, AC motor, and straight elevation, these platforms are ideal for use in tight indoor and outdoor spaces where traditional ladders or scaffolds would be impractical or unsafe.

One of the key advantages of MEWP access is its ease of maneuverability. The platforms can be driven into narrow aisles, confined spaces, and other hard-to-reach areas with ease, making them ideal for use in warehouses, factories, and other industrial settings. The 51cm extendable platform also provides additional working space, allowing workers to perform a wide range of tasks with greater efficiency and ease.

Another advantage of MEWP access platforms is their high load capacity and maximum working height. With a maximum load capacity of 227kg and a working height of 8m, these platforms are suitable for a variety of maintenance, troubleshooting, and inventory control tasks. Whether it's changing light bulbs, performing routine maintenance on machinery, or conducting inventory checks, Mewp access platforms provide a safe and secure way to work at heights.

MEWP access platforms are highly versatile and efficient tools that provide a wide range of benefits over traditional ladders or scaffolds. With their compact size, AC motor, and straight elevation, they offer unmatched flexibility and maneuverability, making them an invaluable asset for any business or organization that requires safe and efficient access to lower heights.

Application

Oil Check Program:

• Lubrication point - hydraulic tank

• Reservoir capacity: 0.80 gallons. (3 liters)

• Lubricating oil - hydraulic oil

• Interval - check every day

Note: Before checking the oil level in the reservoir, make sure the hydraulic oil has warmed to operating temperature.

1. From either side of the machine, open the side access door on the base frame. Locate the hydraulic oil tank on pump unit (3). Check the oil level in the hydraulic tank by looking at the markings on the side of the tank. Tanks are marked with MIN (minimum) and MAX (maximum) markings. The oil level must be within these markings for proper operation.

2. If additional oil is needed, wipe off all dirt and debris from the filler/breather cap area, then add the appropriate grade of oil using a funnel with a flexible nozzle or a plastic squeeze bottle. Add oil until the oil level is between the MIN and MAX marks.

NOTE: Care should be taken not to introduce any impurities (dirt, water, etc.) when removing the cap.

Hydraulic Oil Inspection Procedure:

NOTE: Recommended lubrication intervals are based on machine operation under normal conditions. For machines used in the multi-shift operation and/or exposed to harsh environments or conditions, the frequency of lubrication must be increased accordingly.

Tires and wheels Tire wear and damage

Check tires regularly for wear or damage. Tires with frayed edges or deformed profiles need to be replaced. Tires with severe damage to the tread area or sidewall require immediate evaluation before the replacement machine is put into service.

Wheel and tire replacement:

Replacement wheels must have the same diameter and profile as the original wheels. Replacement tires must be the same size and rating as the tire is replaced.

wheel mount:

Applying and maintaining proper wheel mounting torque is very important.

Wheel nuts must be installed and maintained with proper torque to prevent loosening of the wheel, damage to the nut, and possible separation of the wheel from the axle. Be sure to only use lug nuts that match the wheel taper angle.

Tighten the lug nuts to the proper torque to keep the wheels from loosening. Use a torque wrench to tighten the fasteners. If you don't have a torque wrench, use a lug wrench to tighten the fasteners, then immediately have a service station or dealer torque the lug nuts to the proper torque.

permanently deform the mounting holes in the wheel. The correct steps to install the wheels are as follows:

1. Activate all lug nuts by hand to prevent cross-threading. Do not use lubricants on threads or nuts.

2. Tighten the lug nuts.

3. The tightening of nuts should be carried out in stages. Tighten the lug nuts to wheel torque in the recommended sequence.

The wheel nuts should be tightened after the first 50 hours of operation and after each wheel removal. Check torque every 3 months or 150 hours of operation.

Real Order

Hot Tags: mewp access, Vertical Mast Lift, Vertical Lift, Mast Aerial Work Platform, Indoor Man Lift, Driveable Vertical Mast Lift, Vertical Mast