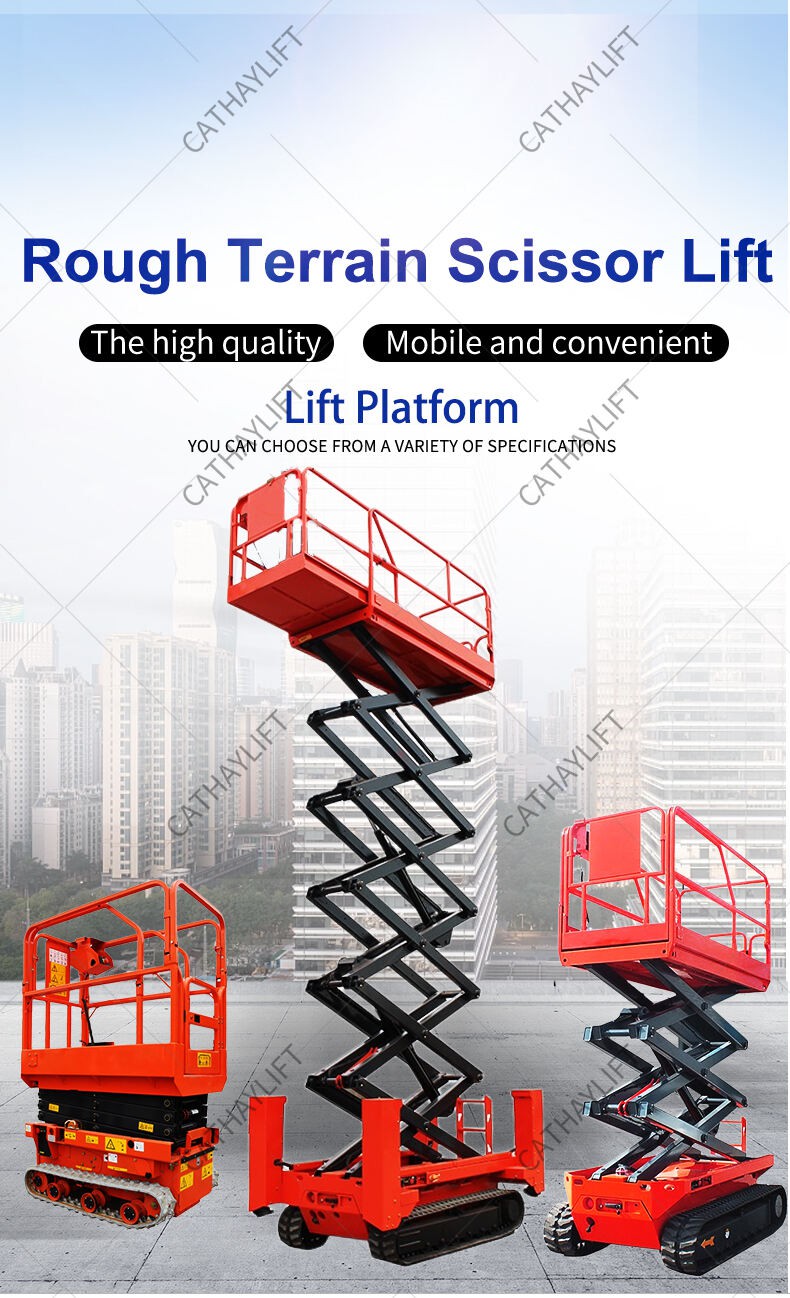

Shandong Cathay Machinery Co., Ltd. is one of the most experienced manufacturers and suppliers of rough terrain man lift in China. We warmly welcome you to buy discount rough terrain man lift for sale here from our factory. Quality products and reasonable price are available.

6~14m Rough Terrain Man Lift

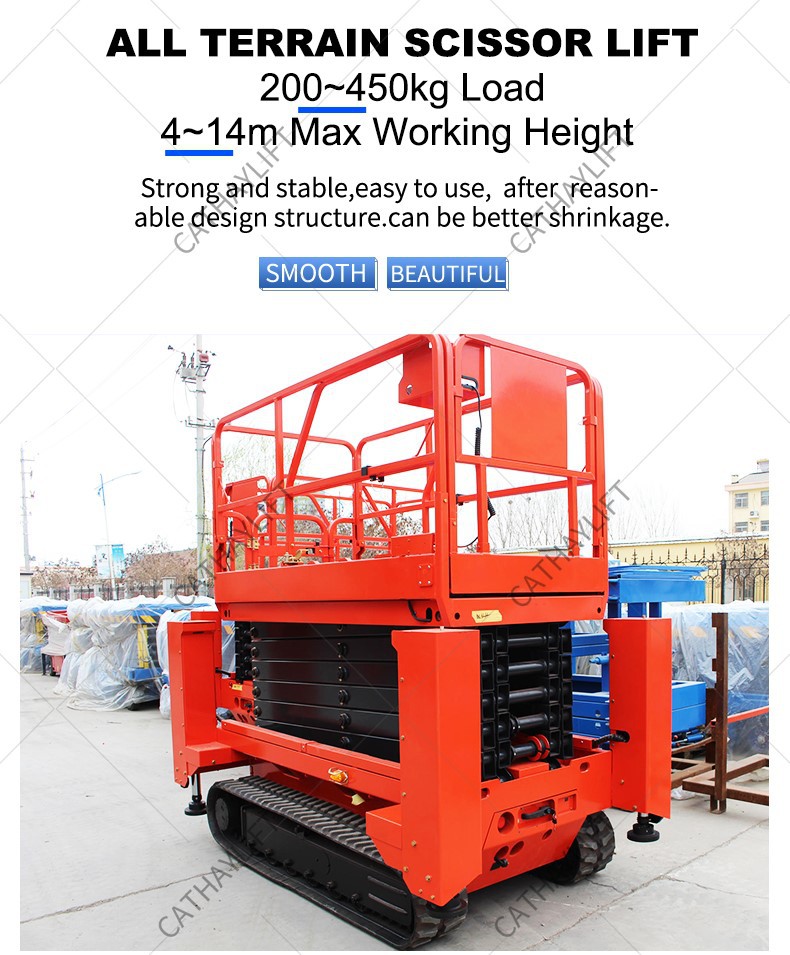

The rough terrain man lift adopts high-quality structural steel, single-sided welding, and double-sided forming technology, imported hydraulic pump station, or domestic joint venture hydraulic pump station, the lift is equipped with balance valves, automatic pressure maintenance, and other safety devices, the platform is safe, reliable and durable. The structure is firm so the deflection and swing of the elevator are extremely small. It has an automatic walking function, three power supply control, and battery control walking are optional, and it can walk under different working conditions without an external power supply, and the handle can control walking.

|

Model Type |

CL-TC04 |

CL-TC06 |

CL-TC06H |

CL-TC08 |

CL-TC08H |

CL-TC10 |

CL-TC10H |

CL-TC12 |

CL-TC12H |

|

Automatic Leveling Hydraulic Outriggers |

None |

None |

Equipped |

None |

Equipped |

None |

Equipped |

None |

Equipped |

|

Working height(m) |

6.5m |

8m |

8m |

10m |

10m |

12m |

12m |

14m |

14m |

|

Load Capacity(kg) |

200Kg |

450Kg |

450Kg |

450Kg |

450Kg |

320Kg |

320Kg |

320Kg |

320Kg |

|

Overall Length(m) |

1.27×0.79 ×1.82 |

2.47×1.39 ×2.28 |

2.782×1.581 ×2.28 |

2.47×1.39 ×2.7 |

2.782×1.581 ×2.4 |

2.47×1.39 ×2.53 |

2.782×1.581 ×2.53 |

2.47×1.39 ×2.67 |

2.782×1.581 ×2.67 |

|

Machine Weight(Kg) |

790Kg |

2400Kg |

2800Kg |

2550Kg |

2950kg |

2840Kg |

3240kg |

3000Kg |

3480kg |

Products Details

Features

1. The power part adopts a special worm gear reducer for lifting. The casing of the machine is an all-aluminum alloy structure, which has the characteristics of lateral torque, low noise, and maintenance-free.

2. The speed control part adopts a Japanese Mitsubishi frequency converter

and uses microprocessor control and IGBT technology to make it reliable and flexible. Complete protection functions provide protection for the inverter itself and the motor.

3. The control part uses a high-precision position sensor to output coded signals to the circuit board for high-speed processing, so as to perform stepless adjustment and control on the up and down turning points of the elevator. The control is easy to operate and has high precision. It can realize multi-break and multi-speed control. It can start at any position. It has upper and lower limit protection functions, high reliability, and no stroke phenomenon.

4. The mechanical parts adopt eight rollers to tightly embrace the square tube guide rail from four directions, and use chains to drive up and down to roll. The roller is made of special material, it runs smoothly without shaking, with low noise and an extremely low wear rate.

5. The control part can also choose touch screen and PLC control.

Maintenance steps

1. Check the oil quality and oil level of the hydraulic oil. The lifting platform rises all the way up. In this position, the hydraulic floor should be 40-50mm higher than the bottom of the box. If the hydraulic oil is found to be dark, sticky, or has foreign matter such as gravel, it should be replaced in time (32# hydraulic oil). Year-end maintenance of lifting platform Checks all hydraulic pipes and joints. The hydraulic oil should be replaced once after 1000 hours of use or should be replaced immediately if the oil is found to have deteriorated midway. Check the filters of the suction and return lines in the tank (annual).

2. Check the engine and battery. The maintenance of power components must also be carried out at the same interval and method as the car.

3. Check oil pipes, pipes, and filters. The pipes must not be damaged, the joints must not be loose, and all joints must be tightened. Remove and disassemble the lifting platform down valve, blow out the plunger with compressed air, then install it and reinstall it. Drain the hydraulic oil and discard it, tighten the joint to take out the oil filter, clean it with compressed air, put it back into the oil tank, and connect the pipeline. (Replace with new oil, do not continue to use old oil. Otherwise, the moving parts in the hydraulic lift system will accelerate wear.)

4. Check whether the rollers of the aerial work platform, the intermediate shaft and the shaft lift bearing, the pin shaft and bearing of the oil cylinder, the hinge shaft of the boom and the bearing are worn or not. All parts are filled with some lubricating oil to prolong the service life of lifting platform components.

5. Mobile scissor lift platform slewing bearing and other hardware. The slewing bearing should be tightened regularly with a torque wrench according to the specified number, and check whether the appearance of the equipment is damaged.

(1) Check the rotating system and lubricate the worm system (adjust the worm if necessary).

(2) Check the fixing bolts, pins, and connecting screws.

(3) Check that all labels, signs, trademarks, etc. are in place and visible.

(4) Check whether all signal lights are normal.

(5) Check the carbon brushes of the DC motor.

(6) Check whether the paint surface is peeled off.

(7) Check whether there are cracks at each weld.

Hot Tags: rough terrain man lift, Good Quality All Terrain Scissor Lift With CE ISO, Scissor Lift, All Terrain Wheel Alignment Scissor Lift, All Terrain Scissor Lift, Motorcycle Scissor Lift Platform, Track Scissor Lift