Shandong Cathay Machinery Co., Ltd. is one of the most experienced manufacturers and suppliers of self-propelled vacuum glass lifter in China. We warmly welcome you to buy discount self-propelled vacuum glass lifter for sale here from our factory. Quality products and reasonable price are available.

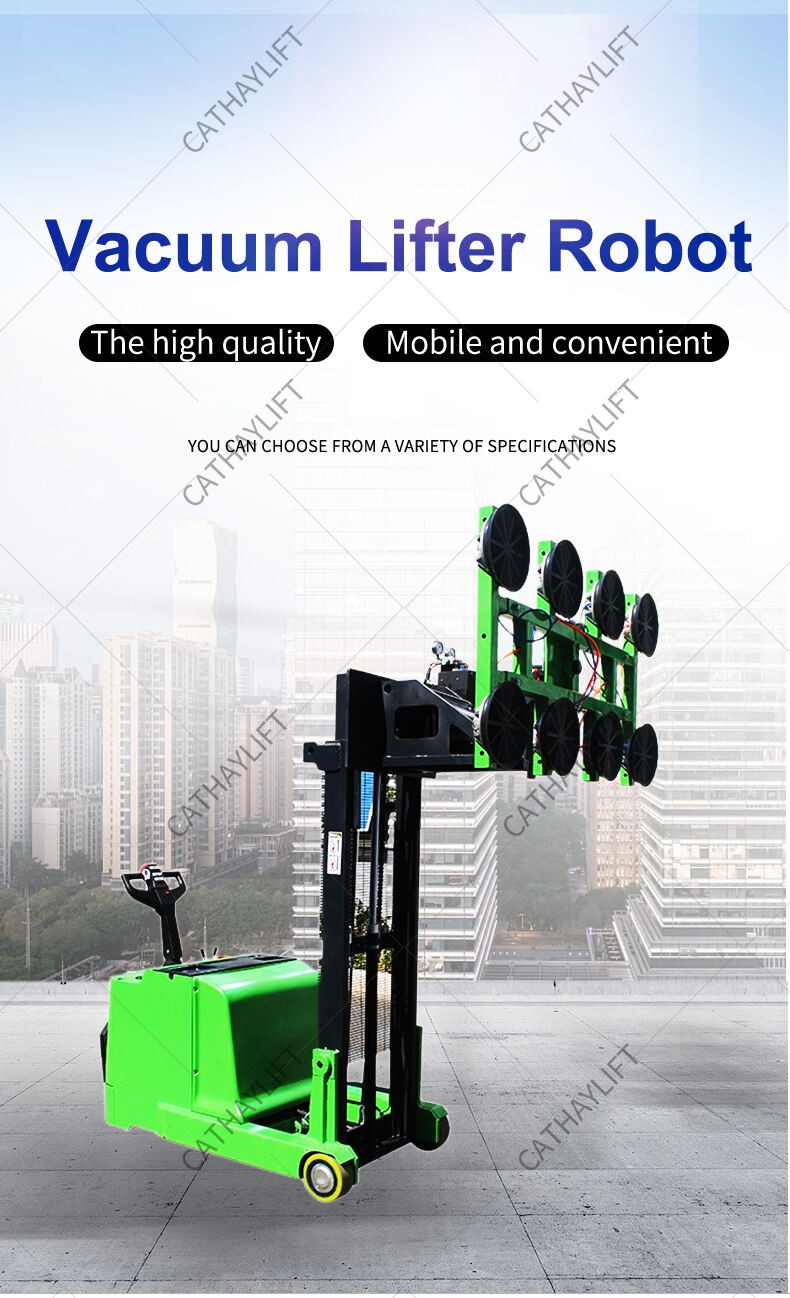

Self-Propelled Vacuum Glass Lifter

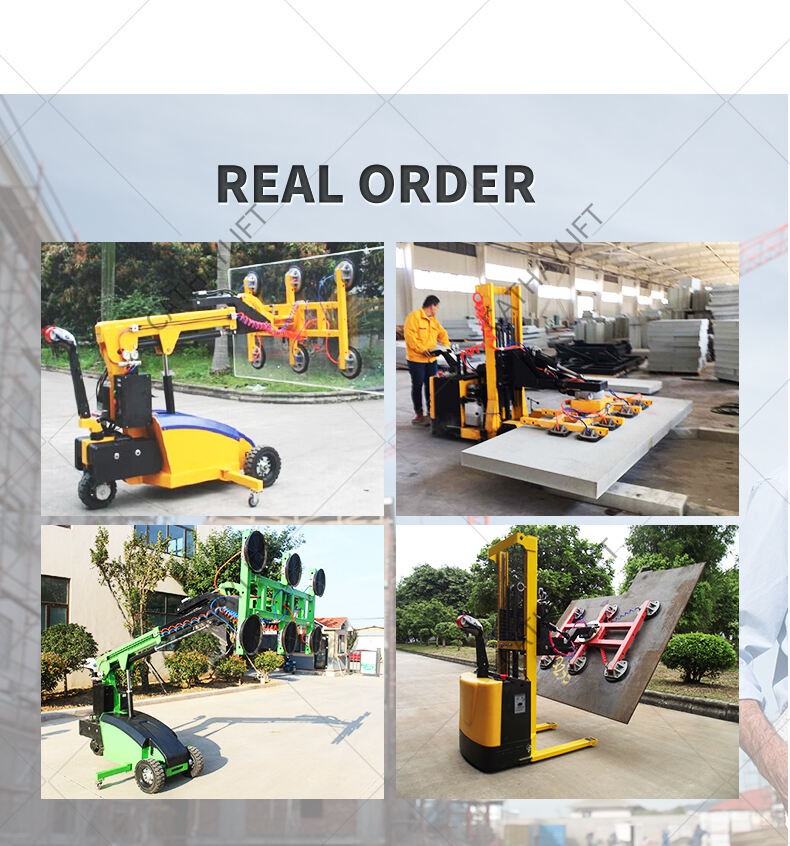

Self-Propelled Vacuum Glass Lifter, a versatile tool engineered for seamless handling of diverse materials like sheet metal and glass. This specialized equipment boasts automatic pressure control, comprehensive safety monitoring, and multifunctional control features, ensuring flexibility, efficiency, and above all, safety in operations. Utilizing advanced suction cup technology, it securely lifts and transports materials, streamlining loading and unloading processes with precision. From industrial settings to construction sites, this lifter offers a reliable solution, empowering users to handle various materials with ease and confidence. Embrace efficiency and safety with the Self-Propelled Vacuum Glass Lifter.

|

Model |

XC-H400(4) |

XC-H400(6) |

XC-H600(6) |

XC-H600(8) |

|

|

Rated Load Capacity |

400kgs |

600kgs |

|||

|

Safe Load Capacity |

200kgs |

300kgs |

|||

|

Lifting Height |

1500mm |

1500mm |

|||

|

QTY of Suction Caps |

4pcs |

6pcs |

6pcs |

8pcs |

|

|

Cap Diameter |

Ø300mm |

Ø300mm |

|||

|

Plate Size (customized) |

1220x1830mm |

2440x1830mm |

|||

|

Load Center |

650mm |

950mm |

|||

|

Drive Motor |

24V/500W |

24V/700W |

|||

|

Hydraulic Motor |

24V/2000W |

24V/2000W |

|||

|

Battery |

2x12V/70Ah |

2x12V/100Ah |

|||

|

Charger |

24V/10A |

24V/15A |

|||

|

Model |

XC-H800(8) |

XC-H800(10) |

XC-H800(8) |

XC-H800(10) |

|

|

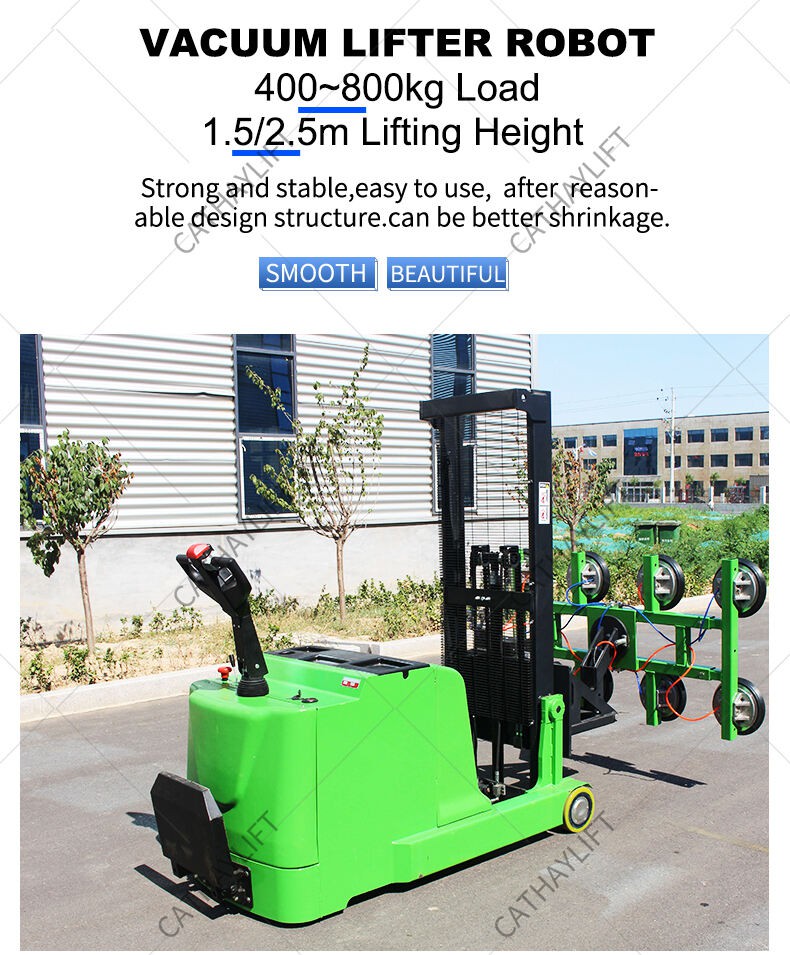

Rated Load Capacity |

800kgs |

800kgs |

|||

|

Safe Load Capacity |

400kgs |

400kgs |

|||

|

Lifting Height |

1500mm |

2500mm |

|||

|

QTY of Suction Caps |

8pcs |

10pcs |

8pcs |

10pcs |

|

|

Cap Diameter |

Ø300mm |

Ø300mm |

|||

|

Plate Size (customized) |

3660x2440mm |

3660x2440mm |

|||

|

Load Center |

1250mm |

1250mm |

|||

|

Drive Motor |

24V/900W |

24V/900W |

|||

|

Hydraulic Motor |

24V/2000W |

24V/2000W |

|||

|

Battery |

2x12V/160Ah |

2x12V/160Ah |

|||

|

Charger |

24V/20A |

24V/20A |

|||

Products Details

Why choose our vacuum lifter?

- Safety: Its self-propelled mechanism reduces the need for manual handling, minimizing the risk of accidents and injuries associated with lifting heavy glass panels. Operators can control the lifter remotely, keeping them out of harm's way during operations.

- Efficiency: The self-propelled feature allows for swift and precise maneuverability, making it easier to transport glass panels through tight spaces and around obstacles. This enhances overall workflow efficiency, leading to faster completion of tasks and projects.

- Versatility: This type of lifter is designed to handle various types and sizes of glass panels, offering versatility in applications. Whether it's large commercial windows, fragile glass fixtures, or irregularly shaped panels, the lifter can securely lift and transport them with ease.

- Productivity: By streamlining the glass handling process and reducing the need for manual labor, the self-propelled vacuum glass lifter significantly improves productivity. It allows operators to complete tasks more quickly and efficiently, thereby increasing overall output and project throughput.

- Cost-effectiveness: While the initial investment may be higher, the long-term cost savings are substantial. The reduced labor costs, minimized risk of damages to glass panels, and increased productivity all contribute to a more cost-effective operation over time.

How to maintain Self-Propelled Vacuum Glass lifter.

- Regular Inspection: Conduct routine visual inspections of the lifter, checking for any signs of wear and tear, damage, or loose components. Pay attention to the suction cups, hydraulic system, controls, and structural integrity.

- Cleanliness: Keep the lifter clean from dirt, debris, and other contaminants that may affect its operation. Wipe down the surfaces regularly and remove any buildup of dirt or grime. Ensure that the suction cups are free from dust and debris for proper functioning.

- Hydraulic System Maintenance:Check hydraulic fluid levels regularly and top up as needed with the recommended hydraulic oil (HL46).Inspect hydraulic hoses and connections for leaks, cracks, or damage. Replace any damaged components promptly.Follow manufacturer recommendations for hydraulic oil replacement, typically every 600-800 hours of operation.

- Battery Maintenance: If the lifter is battery-powered, ensure that the batteries are charged regularly and maintained according to the manufacturer's instructions. Check for any signs of corrosion on battery terminals and clean them if necessary.

- Function Testing: Regularly test the functions of the lifter, including lifting, lowering, and maneuverability. Ensure that all controls are working correctly and that there are no unusual noises or vibrations during operation.

- Training: Provide proper training to operators on the correct use and maintenance of the lifter. Ensure they understand safety protocols, operating procedures, and how to identify potential issues.

- Documentation: Keep detailed records of maintenance activities, inspections, and any repairs performed on the lifter. This information can help identify patterns of wear and provide insights into the lifter's overall condition.

- Professional Servicing: Schedule periodic professional inspections and servicing by qualified technicians. They can perform more in-depth checks and address any potential issues before they escalate.

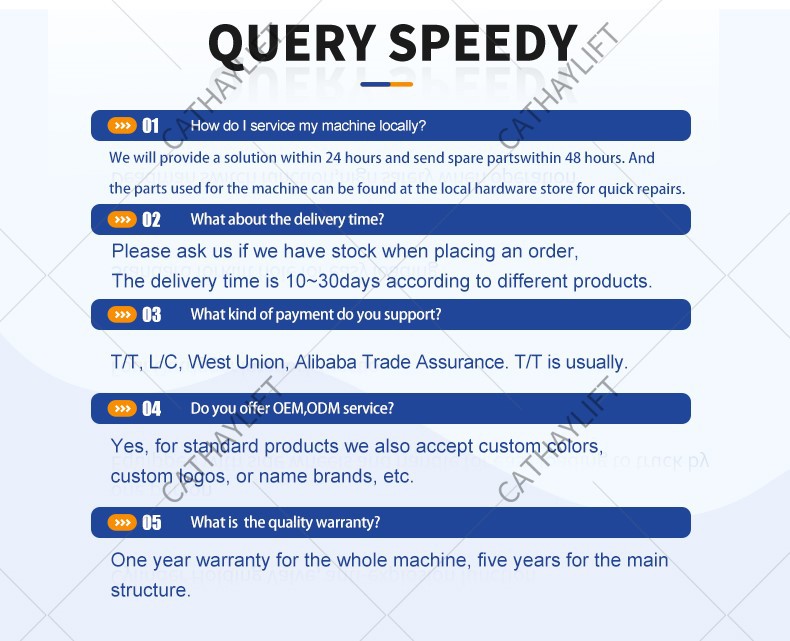

Hot Tags: self-propelled vacuum glass lifter, Table Lifter, Motorcycle Scissor Lift Platform, Hydraulic Loading Dock Leveler, All Terrain Scissor Lift, Warehouse Use Self Drive Order Picker, Aerial Work Platform