Shandong Cathay Machinery Co., Ltd. is one of the most experienced manufacturers and suppliers of manual material lift in China. We warmly welcome you to buy discount manual material lift for sale here from our factory. Quality products and reasonable price are available.

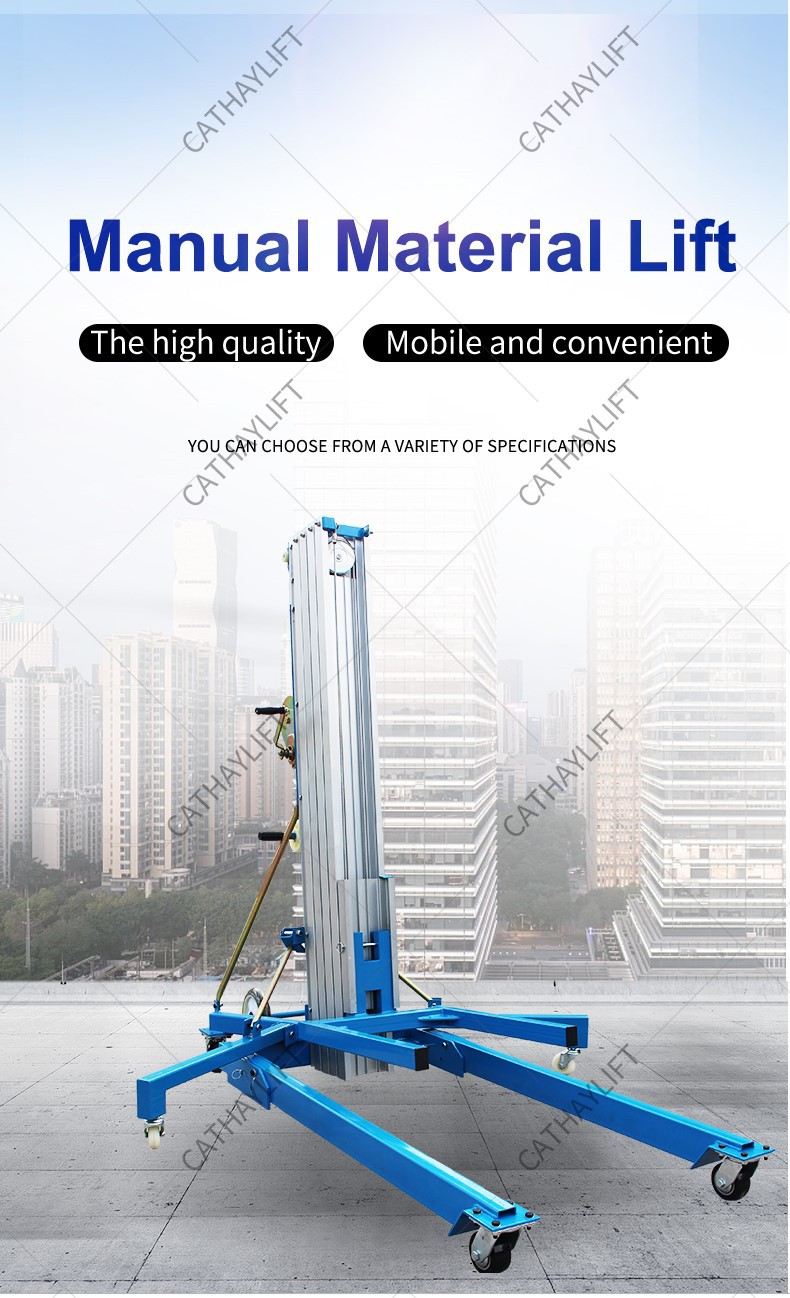

3.5m~7.9m Manual Material Lift

The manual material lifts are special pieces of equipment designed specifically for lifting materials. These lifts are highly advantageous, boasting a simple structure, easy operation, and small size, making them highly convenient to use. They can be transported to different locations, making them highly versatile and suitable for carrying out lifting tasks in various settings. The hand aluminum material lift is a highly efficient and convenient tool for material lifting tasks. The design of this lift is relatively simple, making it highly user-friendly.

|

Model Type |

MAL-35 |

MAL-50 |

MAL-65 |

MAL-79 |

|

Lifting Height(m) |

3.5 |

5 |

6.5 |

7.9 |

|

Load Capacity(kg) |

340 |

320 |

300 |

280 |

|

Fork Size(m) |

0.6*0.7 |

0.6*0.7 |

0.6*0.7 |

0.6*0.7 |

|

Net Weight(kg) |

145 |

170 |

190 |

210 |

|

Overall Length(m) |

1.48 |

1.48 |

1.48 |

1.48 |

|

Overall Width(m) |

0.82 |

0.82 |

0.82 |

0.82 |

|

Overall Height(m) |

2.1 |

2.1 |

2.1 |

2.1 |

|

Operation |

manual |

manual |

manual |

manual |

Products Details

Advantages:

One of the major advantages of the material lift is its compact size and simple structure, making it easy to operate and move around different job sites. It can be brought to different workplaces to carry out the work of lifting materials, making it a convenient and time-saving tool for any exhibition company. With its design featuring hand aluminum, the material lift is light in weight, further adding to its mobility.

The hand aluminum material lift is available in different models, ranging from 3.5m, 5m, 6.5m, and 7.9m in height, with a maximum load capacity of 340kg. This flexibility allows it to meet most material lifting tasks encountered during exhibitions, making it a versatile and cost-effective choice for event organizers.

When using the hand aluminum material lift, it is essential to ensure that it is placed on equipped support legs, which provide stability and safety. The direction of the fork can be easily adjusted to achieve the desired maximum height, after which materials can be placed on the fork and lifted to the required height by cranking the hand crank.

To meet the needs of various customers, the optional height of the hand aluminum material lift can be increased to 7.9m, making it a useful tool on construction sites as well. With its beautiful appearance, small size, balanced lifting, flexibility, and ease of use, the material lift is an invaluable assistant for any exhibition company looking to streamline its operations and maximize its efficiency.

General Maintenance

1. Check both winch handles for wear or bends.

2. Inspect 3” roller wheels mounted on the winch and topmast for damage and smooth rotation.

3. Examine all bolts and nuts to be sure they are tight.

4. Legs, forks, braces, and bases should be dent-free and damage-free.

5. Check pulley covers for damage (indentations) which can restrict the rotation of the pulleys.

6. Make sure the load line is seated in all pulleys and that pulley rotates without obstruction.

7. Check stabilizer legs by lowering them to normal operating position to check the locking mechanism and raising them to check for a smooth transfer.

8. Check all roller wheels for free rotation.

9. Inspect masts and carriage hold-down devices.

10. Raise mast sections to inspect for free, smooth sliding action. Make sure wire slideways are free of dust and oxidation and spray a light coat of silicone lubrication in slideways.

11. Make sure caster wheels and 10” transport wheels rotate freely and are undamaged.

12. Inspect the leg latch mechanism and apply light grease to the spring-loaded plunger.

13. Check to be sure that all three mast covers are attached to the lift.

14. Check the safety brake operation.

Recommended Inspection Every 6 Months:

1. Inspect cable for frays and kinks (see point 1 above)

2. Make certain the winch works freely and that there are no loose or damaged parts.

3. Brake Inspections: Manually raise and support each movable mast section and carriage a minimum of 6” above their lowest position. Use a wooden block with a rope attached to the bottom end to quickly pull on the rope to remove wooden block support from the mast sections being tested. Brakes should engage before the mast section reaches the bottom stop. Use a winch to crank up mast sections to release the safety brakes.

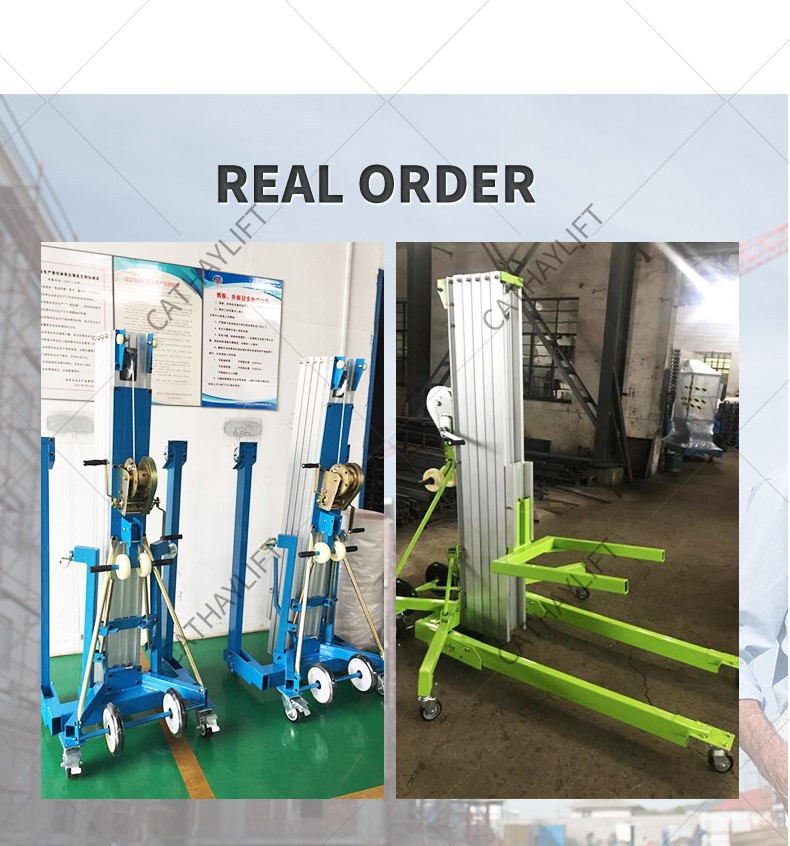

Real Order

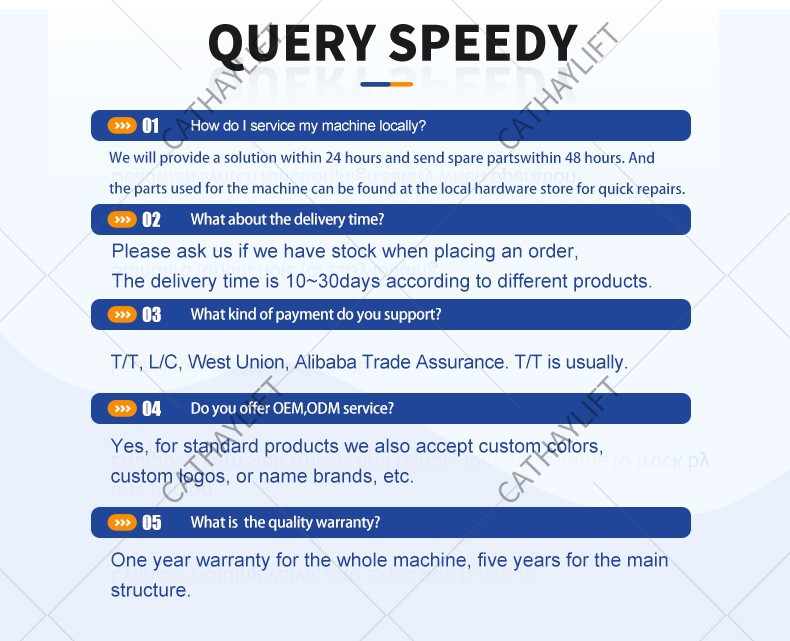

Hot Tags: manual material lift, Push Around Vertical Lift, Push Around Man Lift, Single Person Man Lift, Push Around Mast Lift, Material Lift, Portable Man Lift